Mainboard Mounting

If you disassemble and assemble for any reason (normally not necessary, but unlike many electronics, VEMS ECU is servicable), take the following precautions: take care with the assembly. A thin insulating tape on the 100mm edge cannot hurt. Insulating-sheet under the FET-s+IGBT-s is a must. After assembly, verify that:

- any output pin should not short to the case (verify all output pins, especially inj and ign: with DVM).

- As a measurement, temporarily connect the case with a 10k resistor to pump- (EC18/7=4V), and measure voltage: case voltage should "follow" to appr 4V (+-0.2V). (the case should not short to any other signal like supply-V).

The [new profile with flanges]. See [profile drawing pdf]

- compatible (direct replacement) with the VEMS v3.x mainboards, frontplate, endplate and [gasket]

Options: 0/4/6 holes drilled to our standards for 0/2/3 clamping plates.

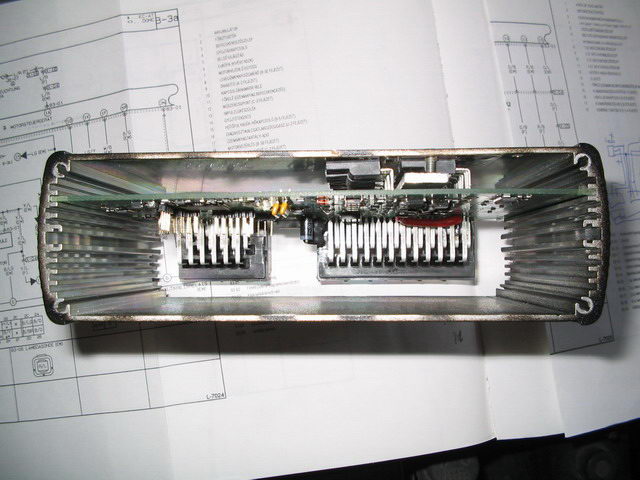

Jörgen made some endplates, here's is a cased VEMS GenBoard 3.0 with EconoSealIII:

Check out how the switches are clamped to the case:

(note: actually TO220 legs are bent in 110 degree; to 90 degrees on the picture which is not optimal)

Check out the new frontplate design at CaseFrontplate.

FETs to the case/heatsink

[picture about the favorite mounting, 2 lines out of 3]

notes:

- there are other options, but make sure you don't swap the gate and the drain of the switches.

- main idea is to clamp max 6 switches (FET/IGBT) with a single (eg. 3mm thick Al) plate, secured with 2 screws. This is fast, and works very well.

- the special plates on the picture with 6 screws and 6 holes are not part of the mounting, they are tools used to align the FETs nicely when soldering.

- the 2 holes (with thread) are not at the centerline of the clamping plate, but divides the 3x15mm Al as 15=6.5+8.5mm.

- The middle plate is reversed, therefore the holes are not equidistant (but 20 + 25 mm apart, see this [picture about the necessary holes for the clamping plate screws] on the top of the Alubos

- FETs from WebShop are insulated by their own coating (but added SIL-PAD insulation does not hurt)

- IGBTs must be insulated from heatsink! This is very important

- Fitting the clamping plate and screws after the genboard is slided into the Alubos is not too hard when the clamping Al plate holes have thread in it (and they do).

Electrical insulator that conducts heat

For usage under the IGBT. WebShop lists it as insulatorsheet ("output drivers" category).

PCB in the Alubos

There would be several slots to slide in the PCB, but we decided to put into the 2nd slot:

10.2 + 1.8 + 22 + 1.8 + 10.2 = 46 mm division sounds right (designing for the worst case, when 2 boards are in the case, both having EC36 connector - on different endplates of course).

Is the 22 mm between PCBs enough? Yes, the EC36 will clear, if the PCB is 98mm, not 100mm. If it was 25 mm or more between PCBs, 100mm could be used. No problem.

The 10.2 mm below PCB is perfect for mounting the FETs with clamping plate and insulator.

0.3+4.5+0.3+3=8.1mm, smaller than 10.2mm, good. Not having through hole or any SMD on the blue side is nice.

See CaseFrontplate

An early v3.1 board with flying loom K-compensational (for ExhaustGasTemp) cable. Usually the LCD and PS2 is made with flying loom (and a 3d frontplate hole hosts pneumatic MAP connection), sometimes LCD and EGT. In this case only an EGT is made flying loom style, because DSUB-capable endplate is used for LCD and RS232 (and PS2 is flying-loom through endplate).

Connection for non-mission critical signals

Signals for LCD, PS2 and some other subsystems are not essential for the engine to run, but they are still nice to have. There are some installer options to get them out of the assembled GenBoard/VerThree:

- [endplate mounted DB25] Note that only endplate with DB25 and DB9 is available now (2 windows). Convenient to have independent connection for - say - RS232. (The endplate with DB9 and DB25 windows is missing the two cutouts for the gasket. At least the one I got. No big problem but maybe it should be there. /Johan Rius)

- DSUB15 fits on the frontplate, vertically between the EC18 and EC36 (but 0 such frontplates have been manufactured, and filing takes some time)

- 6.3 mm Jack is sometimes used for serial port. A 6.3mm male => 3.5mm female adapter plug can be kept in while the notebook is not connected (to protect from liquids).

- simple round cable(s) through the frontplate with gromet. Wire-wire connector (DSUBxx, MateNlock, trimtrio or molex) can be used to disconnect the ECM from the LCD mounted in the car. This is very common for PS2 where "PS2 Extension cable" (WebShop) can be used easily (starts with cutting down the minidin6 connector from the male end). Eg. a cable for PS2 and a 12 wires + shield cable can be used for LCD + RS232. Remember that shield must be grounded on the ECM side only. One of the core wires must be used for the GND signal.

[image of frontplate with MAP signal connection, and holes for LCD and PS2 keyboard]

Misc

- v3.x PCB measures 160x100mm (actually, 160x98 mm but that dimension does not matter)

- [some pictures] that should be cleaned (at least resized) and linked from wiki (or some items from shop)

Mounting alubus case in the car

- Most common place is the passenger side, at the foot

- an L shaped Al (eg. 50x50mm) mounting flange can be used instead of the endplate. 4 drills for the Alubos, and 4 drills for mounting

- the simplest method is just a few wraps of tape, or thin plastic belt around the alubos, eg. between the EC18 and EC36

- some 'rubbery thing between the Alubos (or mounting flange) and the chassis is highly recommended in any case. Otherwise it will make noise and both parties will be scratched.

TODO: pictures of mountings

cnc Case

I've gotten to work designing a new CnC case. It is machined from billet extrusion. Unfortunately this is slightly more costly in machining time and materials than the one made from extrusions but it requires less assembly as the design should be only 3 parts including the heat sink.

There were some special considerations added with this design as well. There is ample space behind the board to mount the power flyback option. I still have to find a means to mount it but I will do this as soon as I have one in my hands.

The top is thick enough that custom CnC lettering or fins can be added. I would like to machine a shallow pocket for a VEMS product sticker in the top. It is also thick enough to be rigid.

The bottom comes with mounting tabs. It is also laid out in such a fashion that a plug can be added to the side with only 2 screws (this is the reasoning for no screw in the middle. The heatsink piece, while bolted to the inside of the case makes contact with the top to allow sufficient cooling.

The entire board can be lifted out by removing only 6 screws.

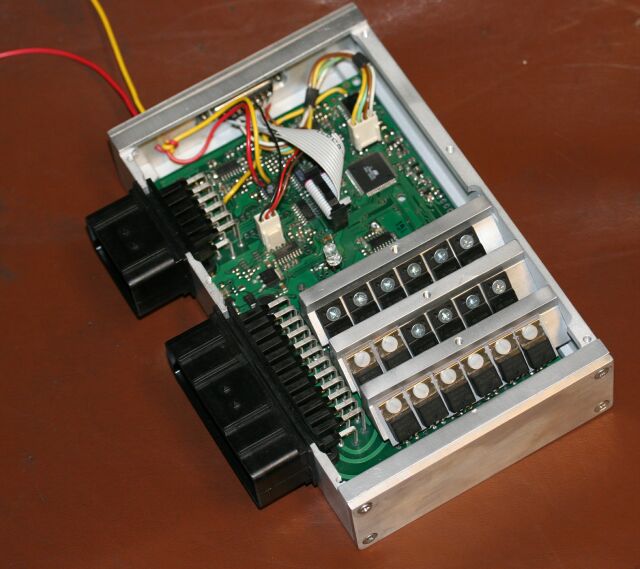

Here is an image of the completed case.

Here are some images of the CAD design. It will be revised slightly for the flyback mounting and I'd like to round the edges.

Overall outside size is 203.20 x 118.11 x 40 mm (8" x 4.65" x 1.575").

This is the older info.

- Unfortunately the connection I had for producing them fell through and the design I helped create became unavailable.

- does this mean that even the CAD files are lost ?

This case is cut from some scrap extrusion. It is in 7 pieces (3 heat sinks the case, top and 2 end caps. There are a couple of options available for the end caps. They include a weatherproof AMP circular plug, DB15 and DB25 as well as a blank. Although currently available in natural aluminum the case may be available anodized in the future.

Completed ECU. As you can see the bottom plate forms the mounting tabs. This may possibly change before production to use some 90 degree extrusion for the endplates. The reasoning behind this is that the EC clips can be difficult to reach if it is flush-mounted.

Considerable effort went into designing the heatsink system. It was designed to be thermally efficient (clamping to the cover) as well as allowing the entire board to be removed from the case in a reasonably efficient manner. I've used nylon screws for the IGBTs with standard heatsink insulators to isolate them from the aluminum heat sink.

The 3 heatsink pieces are already drilled and tapped. The fets and IGBTs can be mounted and then soldered to the board according to the installer's preference.

The completed board is then dropped into the case with the heat sinks attached. 3 orientation screws clamp the heat sinks to the side and once the top is added there are 3 additional screws that clamp them to the top of the case for thermal transfer. If a weatherproof installation is required you can simply coat the edges of the EC connectors with RTV as well as the top and endplates.

This is another view of the heatsink mounting. For orientation in this example the fets and IGBTs were soldered in using about 1mm of protrusion on the leads without trimming them. With the slight bend there is enough play to make up for slight differences.

Will be offered in webshop when manufactured regularly.