Suggestions by Fero: I dont like theese triggerlogs. I'm 99% sure that you use the wrong trigger edge on the primary trigger. The first tooth after the gap seems too long for me, and that could cause problems.

2016.11.20

This is an other AAN 60-2 trigger config

http://www.vems.hu/files/Norbitron/AAN%2060-2/v3.3_u003371-2015-08-06-16.45.15.triggerlog

This triggerlog made in 2015 before first start, without spark plugs.

TDC_delay setup correctly to 88degree with strobe light (and ign adv locked => added later - important).

- Is it possible that there are more than one marking for strobing ?

- or some marking that can be misunderstood ?

- ANS: NO!. It has an original TDC mark on flywheel, and on front belt pulley.

- what ignadv lock angle do you use for this engine ? 0.5 deg ? or lock to 10 deg BTDC ?

- ANS: I locked the ign advance to 0.5 degree when the engine running and setup with (non adjustable old strobe light)

- or some marking that can be misunderstood ?

- Now the engine upgraded and got new camshafts and adjustable camshaft gear

- the sectrig (from camshaft) can cause 360 deg change, or trigger error, but theoretically cannot cause 10 degree change

- The primary trigger wheel and sensor unmodified.

Before the first startup a triggerlog was recorded. http://www.vems.hu/files/Norbitron/AAN%2060-2/v3.3_u011908-2016-11-08-16.45.39.triggerlog

I had to change the tdc_delay from 88 to 71degree. It was about -10degree ignition advance. But how and why?

- we'll inspect your vemslog to see what was the actual spark advance (and why).

- ANS: it should be 9degree BTDC (cranking ignadv)

- the view / gauge group / calc model provides insight into the calculation (eg. if some ignadv modifier is accidentally enabled or set too high)

- it happens that sparkadv is not verified (and different than installer thinks) during strobing. However, in this case strobing was done with ignition advance locked (to nonzero, 0.5 .. 10 deg ???), so wrong ignadv is unlikely.

- NOTE: When i use strobe light i used to lock the ign advance everytime.

- to expedite things, please always mention such circumstances (how things were done, especially when no vemslog provided), otherwise support crew has to go from stone0 (to rule out the simpler things, that are the most common causes)

- CAMshaft trigger= Original Audi AAN HALL sensor, no adjustable, under the camshaft pulley. The camshaft pulley is adjustable. Crank sensor HALL, originaly VW-Audi made. No adjustable, It's on the crankshaft under the flywheel.

Other software/HW trigger settings unchanged.

Please upload vemslog (and .vemscfg would be nice too, although vemslog has .vemscfg info also)

2017.02.02 - New event

The engine maped in november and it was running well since then.

Last week the pistons melted down. Seems clearly the knock detonation on every pistons and cylinder head and this cause the melting down. Fuel delivery was good (2x044Bosch pump), injectors sent to flow metering, Fuel is 100octane Shell V-power. (fuel sample are going to send for inspection).

My teory:

If if a count the tooths from sensor to missing tooth the tdc delay should be around 80-90degree. First time it was 88deg with non adjustable camgear. Then i had to change the tdc delay to 71deg. I found the problem when i mapped, Too high EGT,Weak power,too hight exhaust gas pressure=too high boost(2.5bar with 44mm WG with 0.8bar spring) on 0% boostDC(boost_pwm_max=0). Boost controll valve connected good.

Is it possible that i had to change the ign_tdcdelay value because the adjustable cam gear has been isntalled and the cam signal went away? I think it can cause only 180deg change.

We would like to find the problem because the engine will be build again and we want to solve this misstake. The engine dissasembled the trigger wheel and sensor seems good.

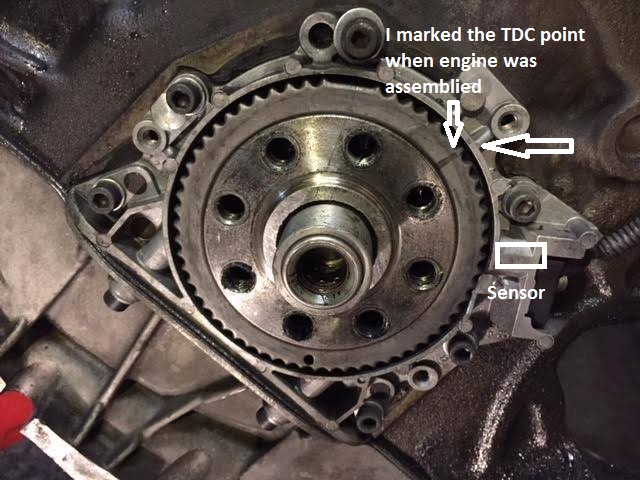

I marked the TDC point when i assembled the engine. You can see on the last pic. It wasn't change.- The wheel didn't slips.

Triggerlogs and vemslogs review report:

- reviewed vemslogs, dont see anything that might offset anything and with locked timing none would be applicable

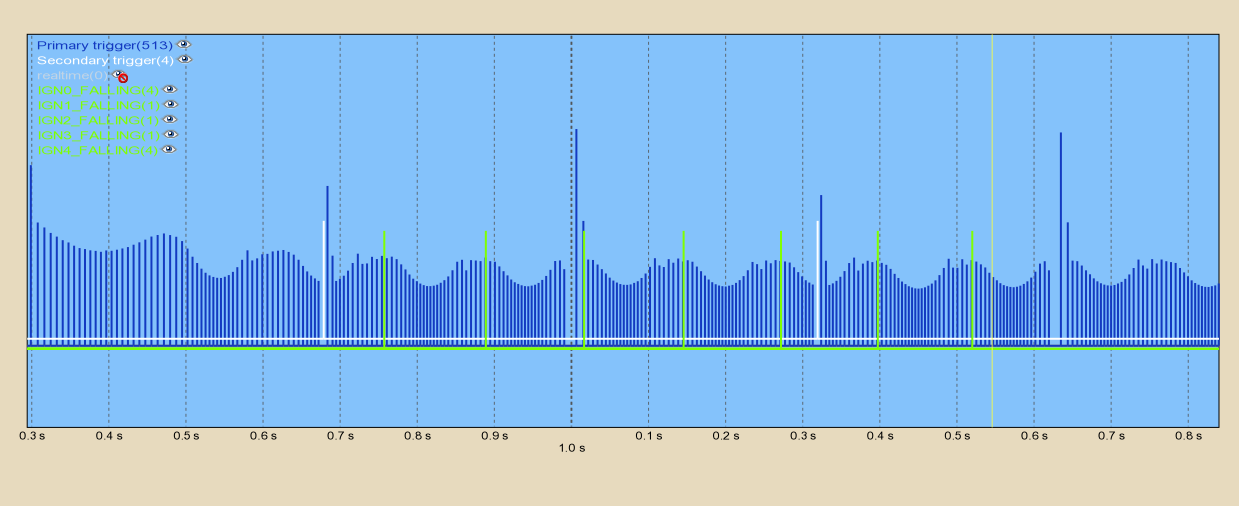

- sectrig just before the missing tooth, about the worst position one can choose, primtrig inverted polarity on both triggerlogs

- first triggerlog (oldest v3.3_u003371-2015-08-06-16.45.15.triggerlog) does not have sparkplugs mounted therefore i cannot compare TDC to spark position between triggerlogs

PNG of the latter triggerlog to point out sectrig position inside missing tooth and primtrig polarity problem:

Heavily modified/rebuilt 5cyl AAN engine 2.5L, 60-2 HALL setup

Custom made flywheel, factory (VR+Auditrigger) flywheel not present.

Some [file attachments].

5cyl 60-2 is very common in Audi-s and Volvos. Usually install is smooth. HALL sensor seems to have failed in this case, after some successful starts. HALL sensors are very reliable nowadays. When they fail, usually some serious circumstance cause them to fail.

It is strongly suspected that insufficient engine ground damaged primtrig HALL sensor.

(The exhaust workshop removed engine ground, and not informed the builders ?)

Primary Trigger

Current stage: failed HALL sensor

- (it was when the engine warmed up)

Expensive VAG *(partnr: Sensor: 030906433Q and trigger wheel/crankcase gasket 030103171L) ... HALL sensor was fitted on crankshaft (not the more usual cheaper aftermarket sensor).

Original harness was modified for sensor pinout, to have +5V at proper place (so the HALL sensor was not connected with wrong polarity even for a second... But insufficient engine ground might have caused problem)

- I made more new and 'stronger' engine grounds!

Changed the original RPM sensor's pinout for the new sensor follows:

- pin1=+5V EC36/28

- pin2=signal EC36/27

- pin3=GND EC36/26

- Crank sensor got a new shielded cable

During (not very systematic) attempts had some tendency to work

- was the triggerlog good with primtrig=falling ? (when capturing HALL trigger, please add primtrig_falling or primtrig_rising in the filename for later ref)

for some time (engine even started at one point), but than it deteriorated RPM=10 (config problem was suspected => random attempts without wiki page and without taking notes => hard to follow and clearly insufficient for support) now primtrig HALL pulls output to 0V all the time, HALL sensor seems to have failed

Primtrig HALL DVM and scope measurements will follow.

Remember to use 2k7 .. 4k7 pullup resistor to +5V if sensor is not connected to VEMS. Without any pullup resistor the sensor output will most likely will be 0V, without any information.

Trigger config

See [FTT] and note that 10 or 11 is not good (nor is it needed or appropriate) for first trigger tooth in this 5 cyl 60-2 setup.

2016.08.12 - Problems solved.

From the first time we had some problem with the primary trigger. I see the trigger teeths on triggerlog but the RPM didn't show. I tried to setup some different settings but didn't help. At the end the battery voltage became too low so we changed to a high loaded. On higer crankning RPM I saw the rpm value, i have had ignition so i could setup the TDC delay and ignition order with strobe light. It wasn't what i was waiting but works . The engine was running while it warmed up and stopped unexpectedly. After this i could start the engine 3times for 2-5second but came trigger error and the engine stopped again. After i couldn’t started the engine again and the sensor didn’t work. When the engine cold down the sensor was working again while it warmed up.

I made a new cable but didn’t help.

I tried to measure voltaes on sensor pins. Measured values: Pin1(+5v)=0.6V with connected sensor/11.6V(disconnected) Pin2signal=0V connected sensor and 4.7V disconnected), pin3=GND

The +5V regulator becam wrong. We had to repair the ECU and after this we applied an outside +5V supply to save the VEMS’s regulator and we changed the primary sensor to another new.

Since the car running well without problem.