The first internal combustion engines were fueled by town-gas. Which can be made from coal, wood (chips, or small cubes), or even waste. Not even complex to make!

Keywords:

- producer gas

- syngas

- woodgas

- holzver-gasser

- downdraft gasifier

Overview

V3 and round firmware was modified to control mixture via PWM-solenoid (there is also a manual valve in parallel so the PWM-valve need not be too big even for bigger engines) to reach lambda-target

- under testing; in v3 the PID-boost can be configured for lambda-target instead of MAP-target

- in the unlikely case that boostcontrol is also needed, alternate boost is still available for boostcontrol

Other (simple) features like "time-relay" for the ash-removal screw or shaker (often windscreen-wiper motor) could be useful.

We built severak FEMA-type downdraft gasifiers and collected experience.

In short, the zones in the FEMA-tarmaker wander up and down, cooling the oxydation zone and creating a HUGE amount of tar (which is somewhat like mineral oil: good in some places, but not good when sticking the intake valve to its seat).

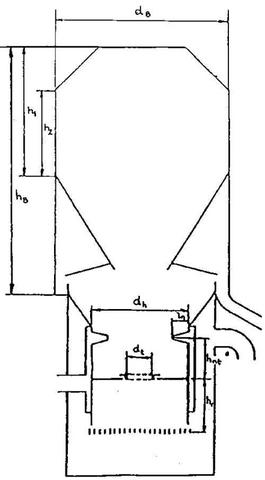

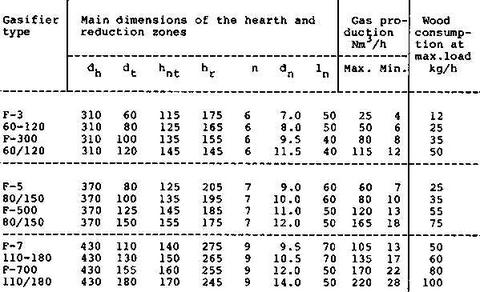

The best 1-stage gasifier design for 2-50 kWe guides air in tangentially, swirling in a toroid at a certain location, keeping temperature up and tar-forming down:

Note that for 30-1000 kWe (typical powerplant cost is 800-1000 USD / kW, so the 1000 kWe is ~ 1 million dollar) the trickier 2-stage gasifier (an updraft and a downdraft or crossdraft combined) seems to be a better idea. It can burn fuel with higher moisture content, and bigger or smaller pieces as well.

Why gasify solid biomass?

For farmers, to use the sunflower seed (in oil form) as heat-engine fuel (for tractors, water-pumping, grinding, heat-pump, generate electricity or other shaft-power) is suboptimal. They have the stalk, straw and weed. The intelligent and environment-friendly choice is to use these growing (CO2 neutral) fuel instead of depending on fossile.

A 100 kW genset generates appr. 400 EUR / day electricity PLUS 400 EUR / day heat (partially warm water, partially exhaust that can be used for absorption heat pump also: for even higher heating value). Appr fuel cost is 200 EUR / day when purchased (only appr 130 EUR for many farmers that have the straw anyway, just need to feed it to the gasifier). ROI (return of investment) could be ~ 1 year or lower.

Combined cycle - brainstorming

There are several choices.

- gasification + spark ignition 4-stroke engine

- very cheap engines. New, or in junkyards. Also cost-efficient to maintain

- gasification + Ericsson cycle (regenerated or recuperated) gas turbine or piston engine probably the BEST cycle!

- unfortunately the hot piston is expensive (the turbine even more expensive). But gasification + spark ignition 4-stroke engine + (Ericsson OR beta-Stirling) can be a relatively cost-efficient IGCC (integrated gasification combined cycle)

- direct burning + rankine cycle: steam engine or steam turbine or ORC (organic ranking cycle)

- a combination of the above.

Links, videos

More links and images [here] (Hungarian. We will continue in English here)

1.6L opel 8 valve engine (C16, or X16SZR) with central injection (the gasoline injector is very low impedance, and 6R8 series power resistor is too high for it, max 1-2 Ohm is OK):

Other trivial improvements and dropped plans

- obvious improvement (in any gasifier): better heat-exchange between the incoming air and the wood-gas output, like gekgasifier.com

- or a simple but efficient long (6m or longer) tube-in-tube counterflow heat exchanger

- temporarily dropped: one that is a big hole underground (covered) with pipes for primary and secondary air-in, gas-out, steam in. A big, corrosion resistant heat-exchanger (condensating for Nx10kW) cools output gas (warming the house at the same time)

- the target is to try the multiphase technology that was used for blue water-gas production (gas rich in Hydrogen, multiple times the heating value of continuous wood-gas). This might be an exteremely cheap and efficient way to reclaim heat with a "rotating" regenerator, otherwise wasted from Otto engines or gas turbines (or other powerplants with high waste-heat temperature, not steam-Rankine cycle of course!), making fuel consumption better

temporarily dropped: using the wood-gas in radial-compressor gas turbines and MembersPage/MarcellGal/DetonationCycleGasTurbine (way too loud)

Use the VEMS Round to control the clean air feed "throttle" of a gasifier in order to improve the output

- vacuum accumulator

- PWM valve

- the VW 2 pin valve with 7.8 Ohm resistance seems to "prell" (using 18-21 Hz, but other freq also when it moves at all).

- pneumatic solenoid valve

- vacuum actuator

- Marcell found several in the junkyard. eg BMW had near the manifold in several 6 cyl engines around 1990.

- most cars have flaps in the cabin-heating / air conditioning system actuated by vacuum valves

- audi (and other VW consortium) vehicles have pneumatic door-lock. These do not seem good, because designed for on/off operation

Stepper would be nice. Unfortunately round does not have enough outputs to control 4 wire stepper.

We have a v3 with blue LCD inside - mounted on a standalone 1.6L 4 cyl engine. The LCD equipped genboard v3 looks very cool TODO: photo, video

For a smallish 20kW synchronous generator we'll use a Crysler 5.2L V8 magnum engine from a Jeep Cherokee

- it has distributer

- HALL/HALL with 8 crankslots (16+1 type InputTrigger/MultiToothNoneMissing )

- when, during testing, we used the TPS as pullup for the HALL, we found that the crank sensor worked well, the distributer HALL did NOT want to pull down the signal properly. The 1.5k was a bit too strong pullup. It worked well with the 2k7 pullup (standard in vems anyway).

- on-engine MAP sensor

- we actually found the HALL supply GND and +5V pins by their shared connection to the MAP and TPS pins

- ...

- Denso alternator seems to have many wires . Why ? Do we need some special signal to enable it ? Or perhaps it has external voltage/excitation regulator ? (I hope not!)

The weird thing about the engine are the fuel railS.

- there is a throttle body injector

- there are 8 port injectors, 12 Ohm (high-Z)

- the 2 fuel rails are connected on 1 side (as expected). But not on the other. There seem to be NO FUEL RETURN LINE for either the TBI nor the port injector rails.

- why ?

- what fuel pressure FPR and fuelpump needed?

- is it better to complete the fuel rails with return lines ?