Injector measurement

I was interested in injector opening/closing time regarding to flyback setups.

All of the below measurements made on a 12 Ohm Hi-Z injector dry -without fuel pressure-, and PowerFlyback installed inside the ECU. No PWM-ing was enabled, pulse width is ~14ms.

NEWS 2007.01.26

I did some measurements with setting cranking RPM range high. Basically it worked fine, but two problems arised:

1. Pulsewidth simply disappears (goes to zero) after some amount of time. Time's between ~40-120 seconds of "cranking". Sometimes it doesn't need to have RPM signal at all just change settings in megatune, and pw on LCD/megatune/in_reality changes to 0000. Switching off/on resolves the problem for the next ~100 seconds.

2. Above 20ms of cranking pw, scale changes to 0.5 msec (so 20.0 + 55*0.5 = 47.5 msec can be specified at max: rarely needed, but it is by design). Above 25.5 msec, megatune displays pw - 25.6 msec.

About the results:

I'm not sure whether this is normal or not. I expected a linear growth of flow with pulsewidth (at least in the higher range).

All of the above pulsewidth values includes all timing (I have set all open times to 0)

2007.01.22

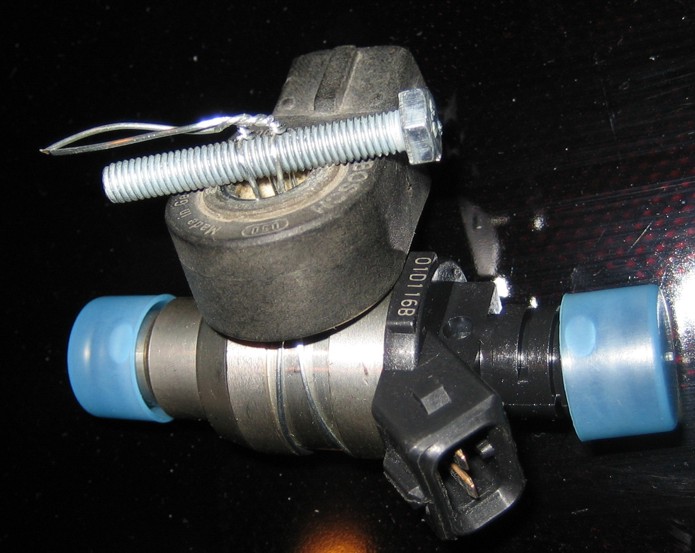

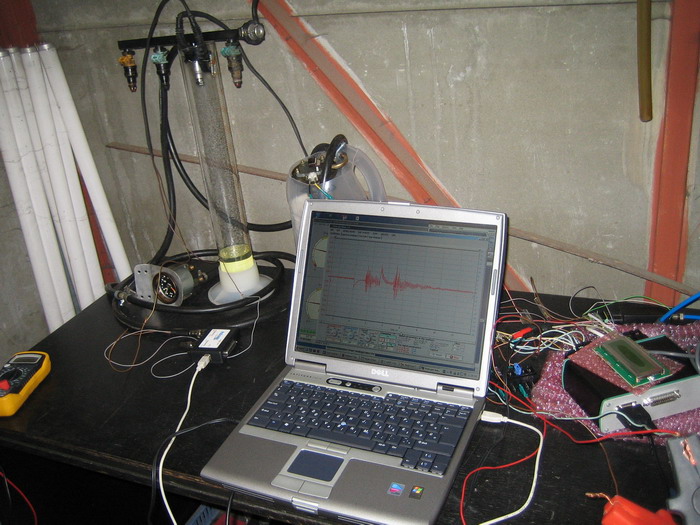

I've put together a flowbench-setup

First tests showed that injector opening time increased slightly according to the fuel pressure introduced (3 bars). No flow measurement data yet.

Question: How can I force GenBoard to a specific pulsewidth?

-Tried "mxofemxofemxp05mxp05" and similar, but no effect at all.

I would use a soundcard ElectronicDesign/TriggerSignalGenerator with 60-2 or similar pattern, and use "cranking RPM" (both low-temp and high-temp values set to same pulsewidth). you can bump up cranking_thresh, but best to apply 290 RPM or similar. Take care (and have multiple fire extinguishers at hand). -It good-and-working idea, thanks.

- You might want to measure (if measuring 'acutal' flow rate) at around 6000 1/min (ie. 100 Hz) or similar (depending your engine maximum revolutions etc.) and around 80-85 % opening time (ie. 8,0-8,5 ms at 100 Hz). //BengtR

- Good idea, I'll check it later, first I'm interested in the idle-area.

Voltage was 12.1-12.2V, voltage/current measurements were made after a 0.3Ohms resistance, so test setup is like:

+12.2V____[0.3Ohms]____*Measurement*____[injector]____INJ-OUT

The results:

Red channel means measurement voltage (or current).

Blue channel means mechanical movement/noise.

- 1. graph is one open-hold-close pulse with no external flyback. Closing time is 1.7ms

- 2. graph is similar open-hold-close pulse with 18V Zener flyback. Closing time is ~0.95ms

- 3. graph is similar open-hold-close pulse with 30V transient diode flyback. Closing time is 0.9ms

It's visible on the red channel that after opening (about 1ms later) current has a pulsation which shows the movement of injector iron core. At the same time mechanical noise started (blue channel).

At closing phase there's not visible current-pulse in red channel but a spike goes well over starting (+12V) voltage which is the inductive "kick-back" or flyback current. Blue channel's mechanical noise shows here the exact position of mechanical injector closing.

As my movement/noise detection (knock sensor) was nearly installed on the injector it's coil slightly picked up injector current, so on the blue channel it's also visible when injector current switched on/off (a single spike before noise).