Trigger setup for Audi S4, 5cyl Direct Fire engine

Audi 2,2T AAN engine

- Primary trigger is VR 60-2 multitooth

- Secondary trigger is a hall sensor, 10-20 Deg Slot fully adjustable (mockup distributor)

- What is the best way to configure this ?

- firmware modification, done in 1.0.25 (seems to work well)

- If we set another_trigger_tooth to 12 (5 per crankrot), and extend the h[2] table to 10 cells, and set dummy values every second cell, also for injectors, divider=02. I guess it would work?

- it would work, but with current stable firmware dwell-time would be limited at high RPM. In short, not a good solution.

- Config http://linkopingsmotorsport.se/config.txt

- make sure you publish actual config (output of mcd) also, not just the intended config. If you mess up global.h (eg. using an old version, forget to update config.mtt file, whatever) this reveals the truth.

- Tables http://linkopingsmotorsport.se/tables.txt

- Datalog: http://linkopingsmotorsport.se/datalog200511141121.xls

- if this is sure not captured with primary_trigger=coil-type config (which results in 24x higher RPM than actual, as in the log), than try http://www.vems.hu/files/Firmware/release/v3_firmware_1.0.25.zip we suspect a syntax thingie in 1.0.24 that could result in coil-type being activated

1.0.25 + MT r027

Config http://linkopingsmotorsport.se/config.txt

Tables http://linkopingsmotorsport.se/tables.txt

Datalog http://linkopingsmotorsport.se/datalog200511281817.xls

Datalog http://linkopingsmotorsport.se/datalog200511281819.xls

Notice drop in RPM, engine never catches up

TODO:

- find cases when RPM drops (trigger error), and find out if anything special happens there (like actuation of a misc output)

Possible causes

- VR waveform shape

- see InputTrigger/RunOut (discussion about waveform updating with this school-example)

These explain everything we've seen!

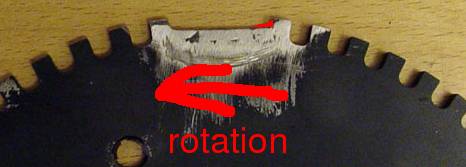

shows

Too high amplitude at the missing tooth.

Eliminating this would likely help a lot. The first attempt did not help. Unfortunately the welding has different magnetic characteristics, so it's a bit different that if the wheel had been machined that way.

You can fill up the small corner-step which leads to the tooth after the gap (considering the rotational direction. before the gap: we don't care):

You can even make the fill (the red part) muuuucccch longer than on the pic, eg. 1.5 tooth long, to span halfway until the gap-mid, don't be afraid of it. The patch you applied seems to have much lower B/H than the base material (not the same material, right?). Even if you filled most of the gap with that material, the the pulse would be just a tiny bit smaller than the normal teeth.

Do you plan to make this ?

Note: no need to mount the wheel on the engine to measure the missing-tooth amplitude. (change the voltage divider 100k/1k to 10k/1k if the notebook sees too low signal)

Also, amplitude varies a lot for normal teeth as well, likely because excentric shaft or wheel. Amplitude is bigger where the sensor sees higher "magnetic flux rate of change", eg. because wheel gets closer to the sensor or has higher magnetic permittivity (mu=B/H).

Most likely reasons:

- distance varies

- very likely! '''Distance measured: 0.7-0.8mm

- wheel is round and centered. How was this measured ? How big is the gap ?. Smaller gap could also help.

- width varies? unlikely.

- magnetic characteristics varies? (unlikely)

Note: wheel must be mounted on the engine to measure if shaft is cenetered.

TODO: Is the sensor mounting bracket firm ?

The 2 captured waveforms show exactly the same pattern, so it is very unlikely to be caused by vibration (why would the sensor vibrate exactly with that phase?).

Possible workarounds

Even if the signal remains trash, it might be possible to solve the problem

- onboard circuit mod

- use a much higher resistor at LM1815pin7 (R181? not sure). 100k is too small, 180k is usual, use 270k

- use reverse VR signal

- since the pulse amplitude is not so deviant with the reverse polarity, triggering could work. (especially apllied together with above circuit mod)

- note that this requires firmware mod, to work with the reverse VR signal

Please elaborate on ECM history. Board version, serial Nr, assembled by, ... ?

Is the ECM unclamped at the moment ? (is it easy to measure inside or solder LM1815pin5 jumper for max arming threshold ?

See also