Best firmware for boost depending on gear is firmware 1.1.47v2

http://www.sendspace.com/file/k2n7hc (megatune with firmware).

idea and programed by Andrey

http://www.vems.hu/wiki/index.php?page=MembersPage%2FAndrey%2FSpeedSensor

I advise to use 16x14 firmware, becouse 12x12 firmware has a bug with tps scaling(tps scaling values are shifted by 4, so value 62.5% is 12.5%, 75% is 25%.. first value in boost PWM table is 62.5% tps..). I can explain better this bug if someone use 12x12 firmware.

There is two types of strategies.

First open loop stratagie.

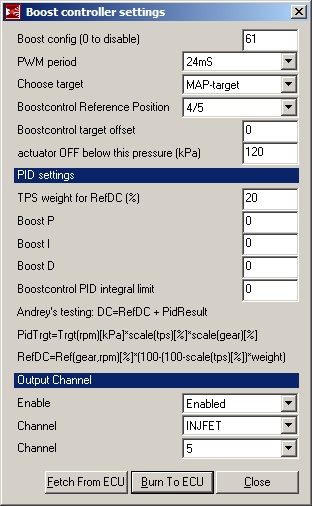

You need to set PID controler to 0, like this

tps weight for refDC is to reduce(or eliminate) surge at high rpms and low tps.

If you have drag car only, you can put 0, but for street car i recommend 15-30%(spool with 0% i batter).

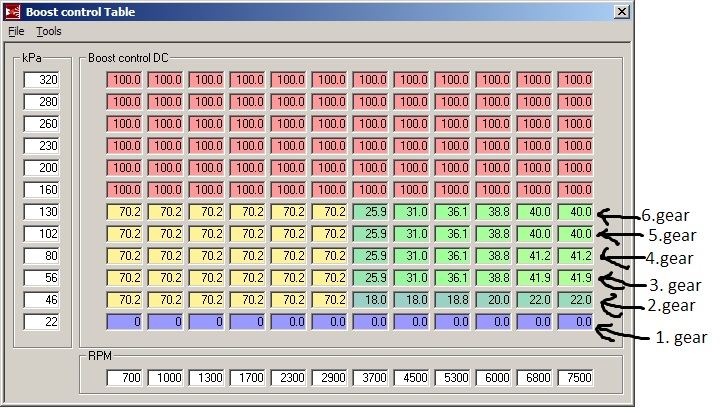

Next PWM table.

first row(from down) is 1. gear, second 2.gear...

RPMs are rpms :)

So in my table, in first gear is boost solenoid disabled, so boost is determinated with spring of waste gate(0.8bar cca).

In second gear pwm values are 70.2 till 2900rpm for faster spool(wg is closed till 3200-330rpm). At 4500rpm target boost is 1.2bar, but above 6000rpm boost rises slow to establise uniform torque till rev limit.

3. gear more boost(2.3bar at highs rpms) :)

Closed loop.

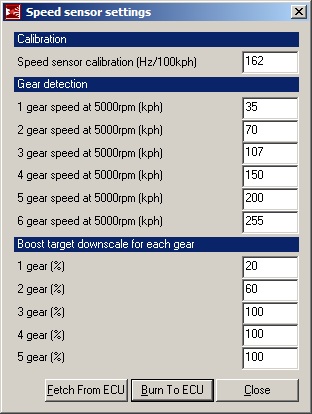

You must set rpm target boost, tps scalning and speed sensor settings like:

And you must set reference position for boost solenoid like in open loop.

You can put small values in PID controler and small intergral limit(8 integral limit= 1% pwm of boost solenoid change) so closed loop can do only small changes to reference position.

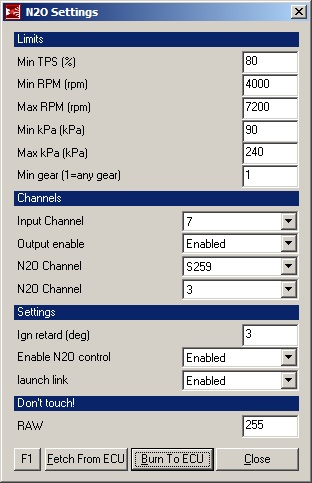

You can use that methode for N20 controlling(if you have PWM value for nitro). You can use N20 settings.

for enabling relay that give power to solenoid only when button for N20 is pressed.