Pagename is broken. The correct name of the feature is "GEAR depenDANT boost" (right ?)

In 1.1.66(still testing) are made small upgrades. First you can use gear dependant boost control(PID closed loop or open loop) and in the same time you can use boost alternate for water injection, second boost pwm valve(useful for external wastegate), nitro(N2O)...

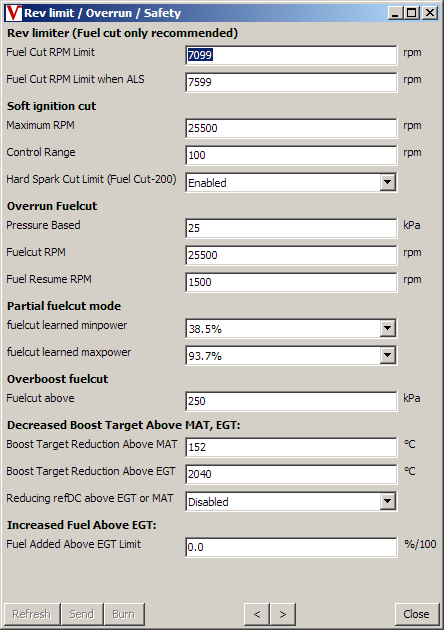

And now egt and iat can affect to boost ref DC(only when boost dependant refDC table is enabled). So when EGT or MAT is to big, boost will be lowered.

set Reducing refDC above EGT or MAT

for 10C MAT it removes 7.8% of DC(absolute, not relative. So if refDC is set to 50%, when MAT is 10C above mat threshold refDC would be 42.2%)

for 40C EGT it removes 7.8% of DC(absolute, not relative. So if refDC is set to 50%, when EGT is 40C above mat threshold refDC would be 42.2%)

Open loop strategy

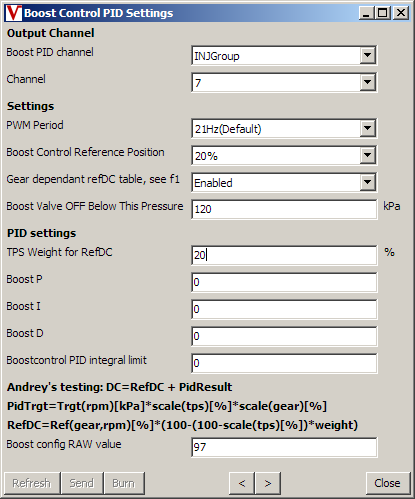

In this strategy ecu just look in GEAR dependant boost refDC table according to car gear and rpms(table is 12x6 big). After that ecu only applies TPS weight for refDC and Reducing refDC above EGT or MAT(if is enabled). No matters what boost_target or BOOST TPS scaling were set.

Basic settings for open loop:

tps weight for refDC is to reduce(or eliminate) surge at high rpms and low tps.

If you have drag car only, you can put 0, but for street car i recommend 15-30% (spool better with 0%). And control of car when starts to lose tracking is better. Because if you little release throttle ,waste gate would open more=> less boost.

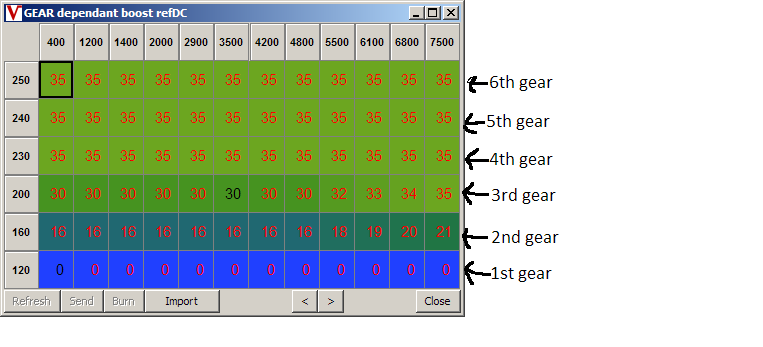

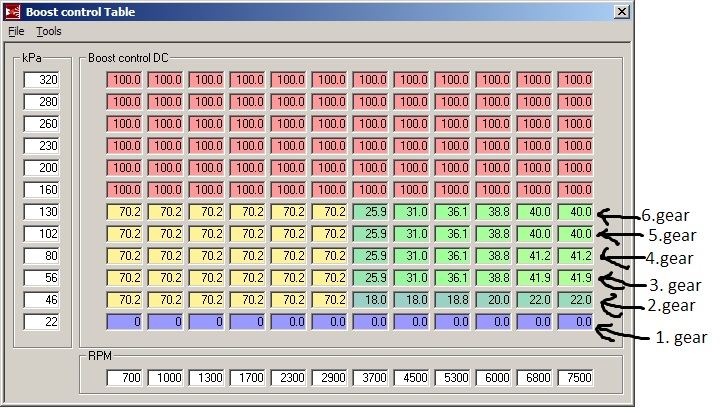

Example of GEAR dependant boost refDC

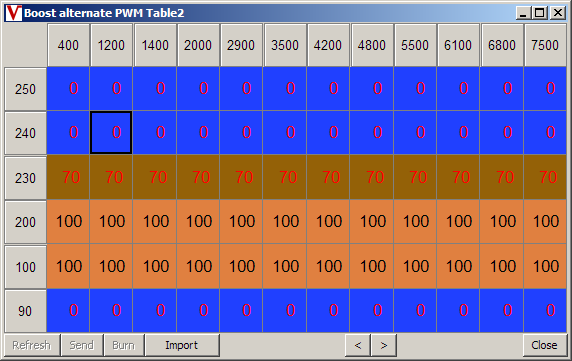

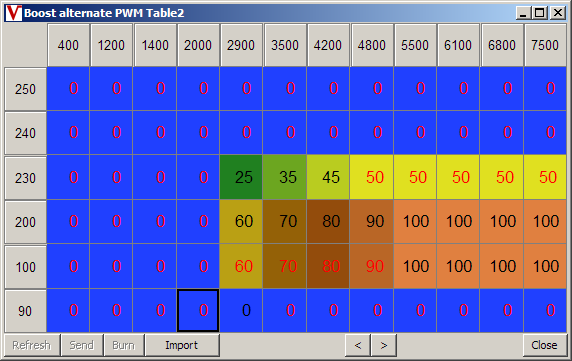

And you can also use boost alternate PWM table at the same time, like(absolute mode):

If you use Gear dependant refDC table and absolute mode, then alternate PWM table is smaller(12x6). If you disable Gear dependant refDC table then is normal size (12x12).

For simple mode(open loop or closed loop) table is 12x1 regardless if Gear dependant refDC table is enabled or disabled.

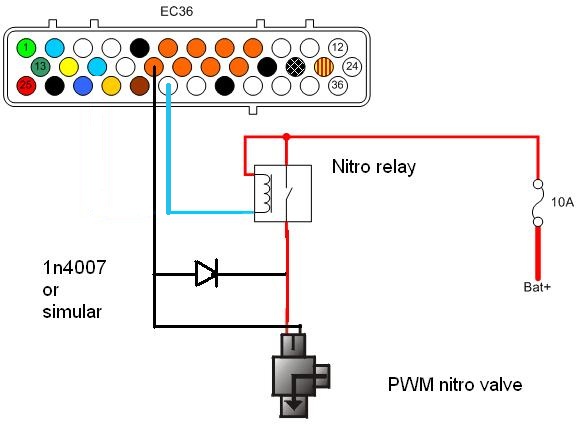

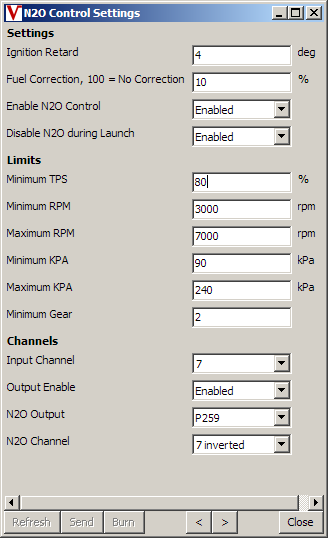

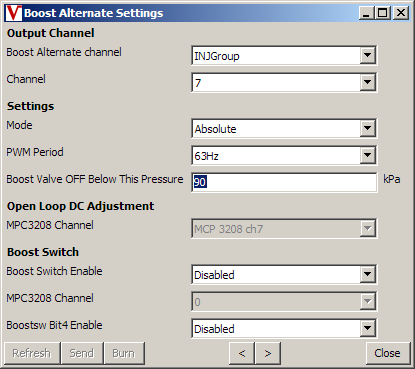

example for faster spool with nitro with alt boost

Schematic:

Config:

In that way target boost for faster spooling is 1.4bar of boost.

With that table you can use gear dependant boost control at the same time.

Some history:

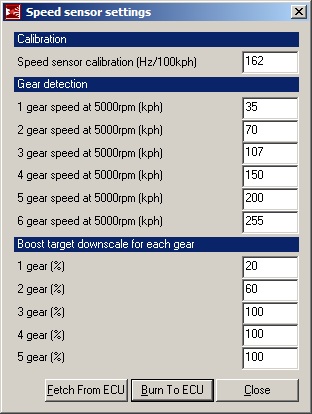

Originally implemented by Andrey in 1.1.47v2. See MembersPage/Andrey/SpeedSensor

I advise to use 16x14 firmware, because 12x12 firmware has a bug with tps scaling(tps scaling values are shifted by 4, so value 62.5% is 12.5%, 75% is 25%.. first value in boost PWM table is 62.5% tps..). I can explain better this bug if someone use 12x12 firmware.

2010-01 it is getting ported to 1.1.66 (hopefully without effecting any other mode, if this feature is disabled).

There are two types of strategies.

Open loop strategy

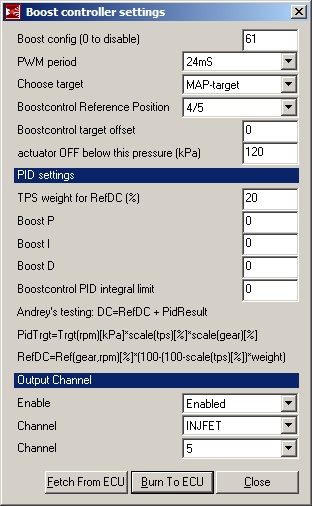

You need to set PID controler to 0, like this

tps weight for refDC is to reduce(or eliminate) surge at high rpms and low tps.

If you have drag car only, you can put 0, but for street car i recommend 15-30% (spool better with 0%)

PWM table

first row(from bottom) is gear 1.

So in my table, in first gear is boost solenoid disabled, so boost is determinated with spring of waste gate(0.8bar cca).

In second gear pwm values are 70.2 till 2900rpm for faster spool(wg is closed till 3200-330rpm). At 4500rpm target boost is 1.2bar, but above 6000rpm boost rises slow to establise uniform torque till rev limit.

3. gear more boost(2.3bar at highs rpms) :)

Closed loop strategy

You must set rpm target boost, tps scaling and speed sensor settings like:

Set reference position for boost solenoid like in open loop.

You can put small values in PID controller and small intergral limit(8 integral limit= 1% pwm of boost solenoid change) so closed loop can do only small changes to reference position.