VolkWagen Corrado G60

It's a Stock g60 engine with some modification in the cylinder head.

It has a gt25 turbo and big intercooler.

VEMS Options:

* 8 ignition

* 310 kpa map

* Lcd

* Knock

* Egt no

I made the wireing harness with new cables. Only the vr sensor cable stayed the factory shielded cable. We made a 60-2 sensor wheel from az opel corsa (this is the smallest) and a matal frame to hold the sensor. The sensor is a vr sensor from a 3,0 liter opel engine 24v. And we had some issues because after we made the forst start the engine was smooth and perfect sounding but when we incrased the rpm the trigger sign stoped, approximately at 2500 rpm. Than we tried t change the sensors oriation to the wheel and we had 5000 rpm one time. But than it was the same. When the car is in motion the trigger error sign is on from 1700 rpm and the car start to lug and the rpm won't incrase. We tired 3 vr sensors and 2 vems ecu's and used a working config from another car.

Next time I will make a scope mesure for further ivestigation, and an alu frame for the sensor galvanic detachment.

I would be pleased if anybody could write some thought of the problem.

We changed the frame and the sensor to the opel sensor but nothing has changed so I will make an osciloscope mesure in the weekend.

In the weekend we scoped the vr sensor and we find out (with Marcel's help) that the sensor wheel is the bad part of the trigger.

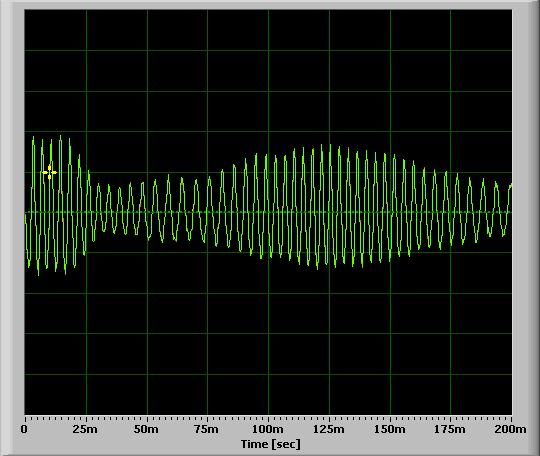

The owner of the car made the wheel from an Opel Corsa trigger wheel because that is the smallest, and he welded the metal sensor wheel to the vbelt wheel. The only problem was that the welding changed the steel's magnetism. The sign was too high in the first part and too low in the middle. The vems input trigger setup filters the sign and the low signs have been cut of. This was the reason of the missfire. At 2500 rpm the missfire was so much that the enginge wouldn't rev more. Then we welded the sensor wheel around to smothen the magnetism. The sign was like so afterwards:

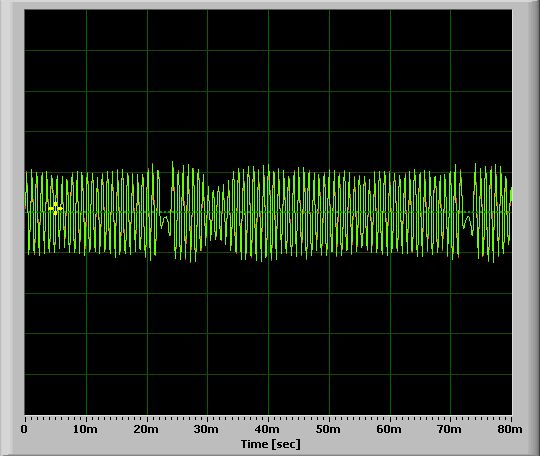

Than we tried to rev the car but it stoped at 2500 rpm and the sensor sign was like this:

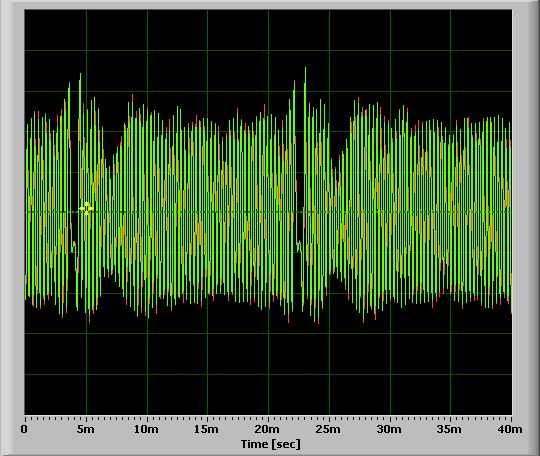

We looked at the sensor wheel and we saw it has a little deformation from the welding from the 7 and the 10 trigger tooth. We hammered the deformation and finaly the engine reved to 7000 rpm limit where the target was.