I have switched from a megasquirt to a Vems but have now problems with the trigger signals.

Primary and camsync trigger is hall.

Vems cannot properly detect trigger sequense from Nissan 300ZX hall module with 12-1 triggerwheel.

Car is race V8 engine, high compression and cranking at approx 80..113 rpm. The cranking rpm varies very much due to the high

compression.

When turning distributor by hand with ocsilloscope connected there is no doubt where missing tooth is. Allways 11 tooths between the

missing tooths and the camsync signal comes on triggertooth 0 (first tooth after missing tooth)

I have also tried disabling camsync all together, but it makes no difference.

When turning the distributor by hand (approx 80..100 rpm in vemstune) sometimes the sparkplugs ignite.

The rpm signal in vemstune (1.5.24) seems to be very stable. No flickering rpm signal.

Triggerlog when engine is cranking. (with wrong ignition output settings, but trigger setup is correct)

http://www.vems.hu/files/perboddum/cranking.triggerlog

Triggerlog when distributor is driven by hand

http://www.vems.hu/files/perboddum/turnbyhand1.triggerlog

http://www.vems.hu/files/perboddum/turnbyhand2.triggerlog

Vems config

http://www.vems.hu/files/perboddum/setup6.vemscfg

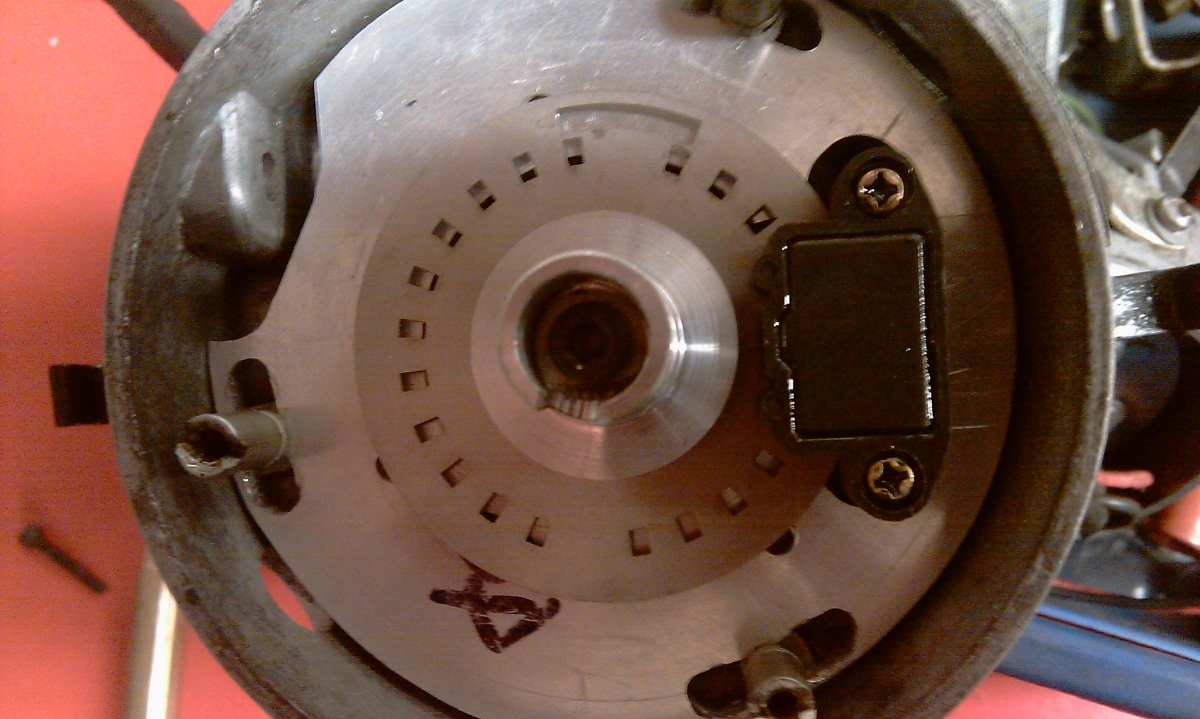

Picture of triggerwheel 12-1

I really need some help to get this Vems setup to work.

Per i have reviewed your triggerlogs and indeed the periods between teeth seem very irregular.

1) Lets start out with with following, could you make a triggerlog of engine cranking 8-10 seconds without injector and ignition fuse to verify if the irregular periods are caused by some noise issue.

2) Secondly could you make another triggerlog (again 8-10 seconds) but then spinning the trigger not by hand but by some something with stable rpm (perhaps use a battery powered drill), that way we can verify, if with stable RPM the trigger periods are even.

If you upload both these triggerlogs to your memberspage i will review and provide hints on how to proceed.

Best regards, Dave

Thanks Dave

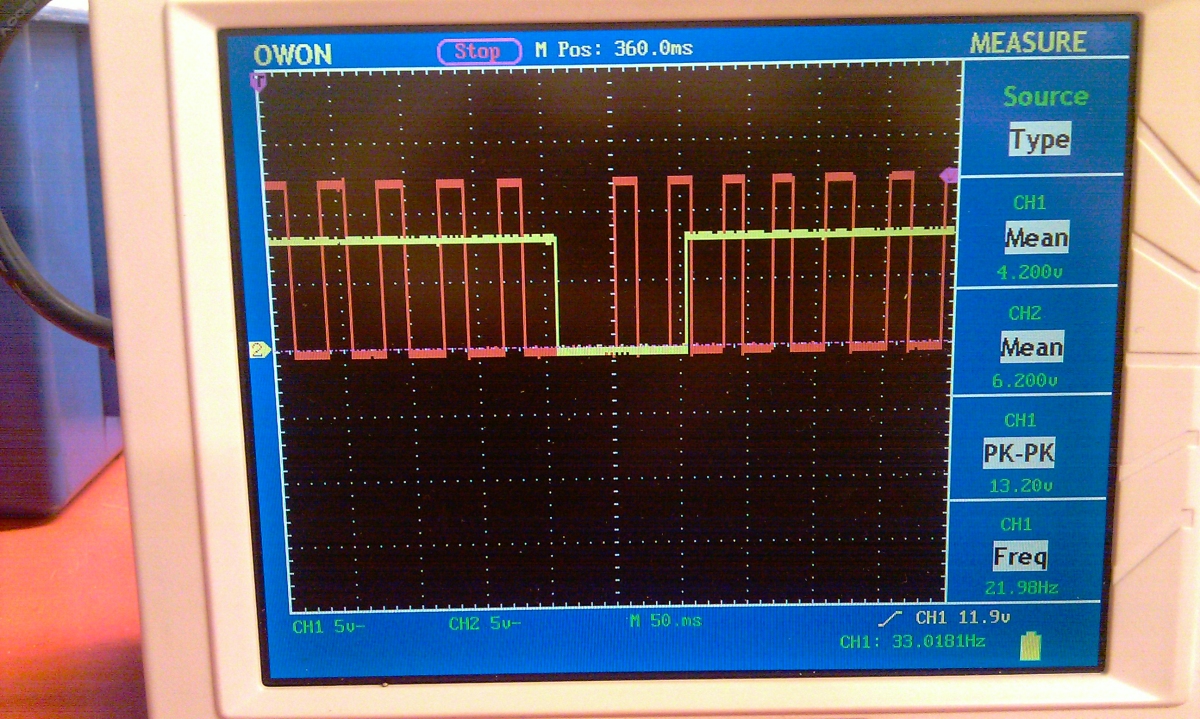

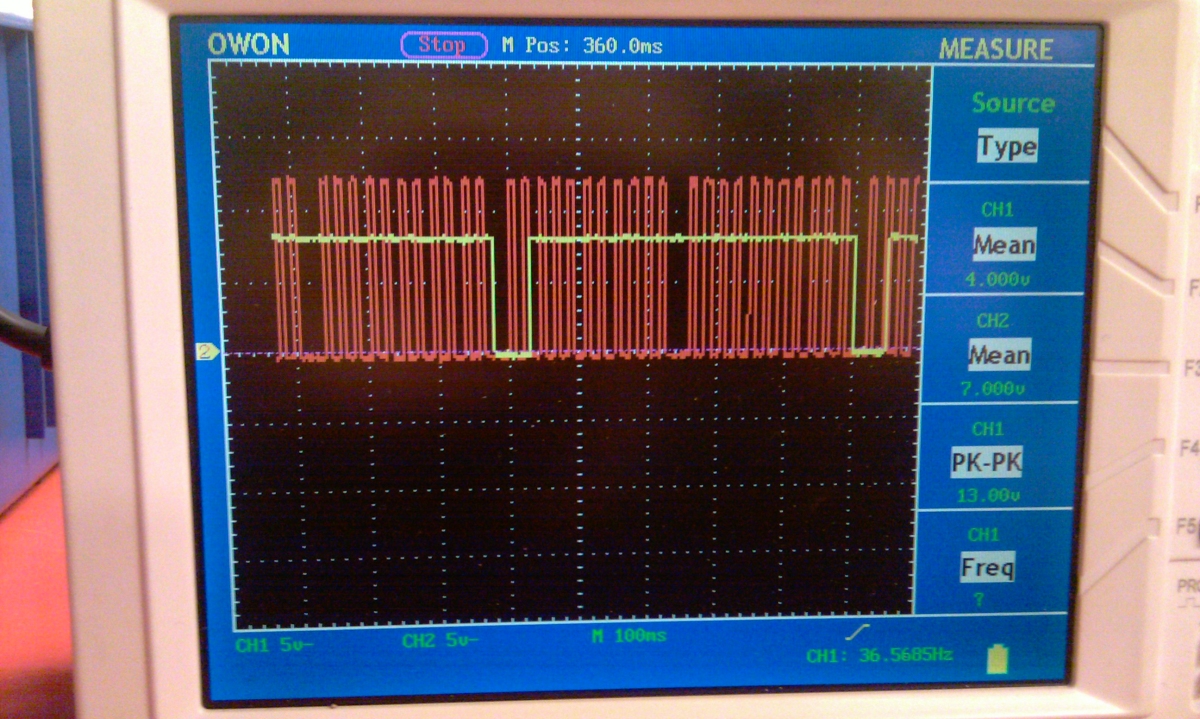

Scope of triggerwheel 12-1 with power drill at approx 200 rpm

I have done some more test with power drill (50...120 rpm) and the distributor connected to Vems.

Vemstune displays the rpm but as soon as rpm drops and then gains rpm again I often get PRI.trig error in Vemstune and the sparkplug stops sparking.

It seems to me that it is a combination of low rpm AND varying rpm at the same time that confuses Vems.

I can have steady 60 rpm and there are no trigger errors and the sparkplug ignites

Tomorrow morning I will try install the distributor and make the logs

Hello Per,

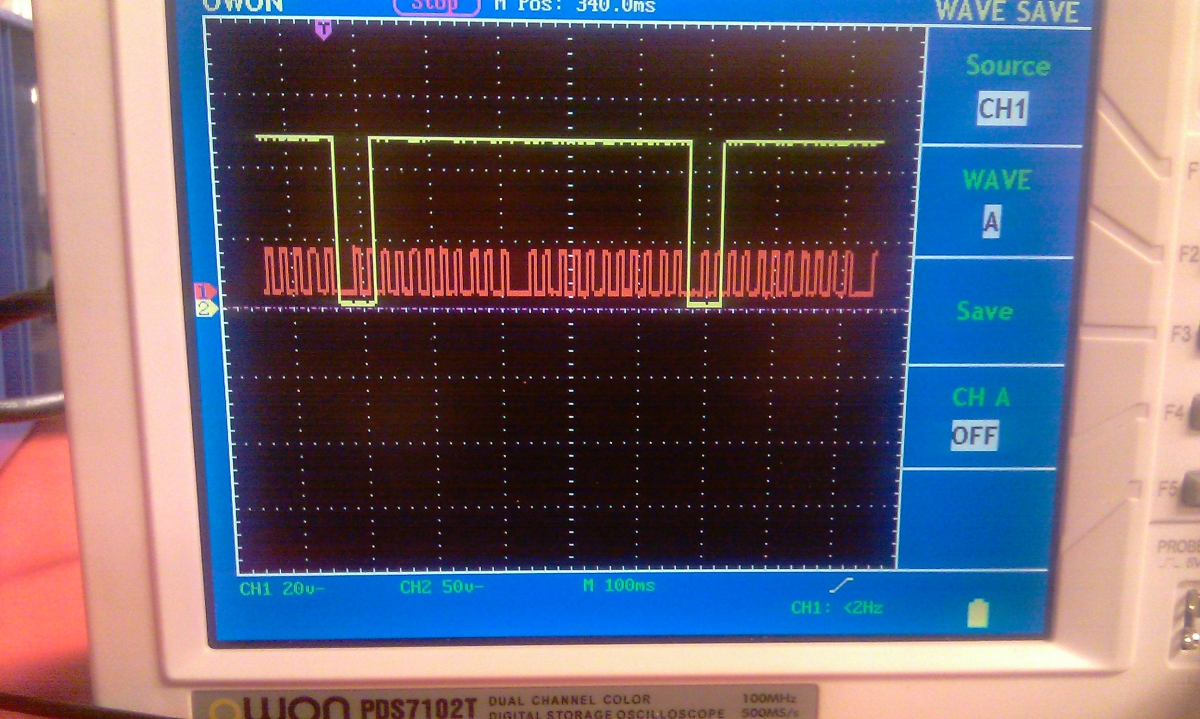

When reviewing your scope shots it seems there also is a very slow rise rate on the primary trigger pulses (red signal, ch1) could you set both probes to the same amplification, set the scope Y range the same for both channels, trigger on yellow signal (ch2) rising edge and make a much smaller timebase shot so i can accurately see:

1) falling secondary triggger (yellow, ch2) in center of screen and one or two primary edges (red, ch1) left and right.

2) additonally please supply the VEMS triggerlogs (.triggerlog files) as requested in previous query.

3) make sure the secondary trigger is enabled and connected to the VEMS when making these.

Best regards, Dave

Distributor connected to Vems and drill operated.

http://www.vems.hu/files/perboddum/drill1.triggerlog

http://www.vems.hu/files/perboddum/drill2.triggerlog

I cannot make a triggerlog or normal log, because Vems constantly looses the serial connection (physical serial COM1, not USB adapter) during cranking. Vems supply voltage is around 9.35 volt during cranking.

Note:Battery is in the back of the car.

Hello Per,

If the VEMS looses serial connection during cranking this means the ecu resets (most likely because of voltage dip during initial cranking engage) but if the ecu does not reconnect during cranking there might be some problem with the integrity of your GND wires from battery to chassis, GND from chassis to engine or VBATT cable from battery in the back to the engine. While performing the other checks it makes sense to verify these also (for good connection, corrosions, sufficient size etc.)

Best regards, Dave

Thanks Dave.

The car is rebuild from scratch with new wires in 2009. No rust or corrosion what so ever. Have only run some 4000km.

Connected 2 batteries and the engine fires up, but still looses sync at 1500 rpm. No camsync.

http://www.vems.hu/files/perboddum/running1.triggerlog

http://www.vems.hu/files/perboddum/running1.vemslog

With camsync.

http://www.vems.hu/files/perboddum/running2.triggerlog

http://www.vems.hu/files/perboddum/running2.vemslog

MembersPage/PerVolvo - Volvo 960 VEMS