Subpage of MembersPage/MarcellGal/PowerAndTraction

Found the 100 lost horses:

- the pre-throttle 60=>70mm rubber was clamped badly under (where hardly seen under the throttle)

- NOTE that measuring pressure drop in operation did not reveal this (it would have been possible, but not easy measurement). Pressurizing in the garage showed it immediately

- the post-throttle seal was also leaking a bit

- One of the PTC thread was bad, and a small nipple was open but these were minor

MAP now reaches 280 kPa easily. TODO: cleanup the remaining texts from the 206 kPa hassle

Hunt for the last 100 horses; tests in the 206kPa hassle

- I've installed a blind-gasket (triangle sheet cutout from the side of a PC ;-) after the wastegate to see if boost is willing to climb up this way

- if boost still stays below 220kPa, than we either

- have a serious leak at the exhaust manifold

- or the K26/27 turbo-rebuild (done by professionals, see MembersPage/MarcellGal/PowerAndTraction and MembersPage/MarcellGal/PowerAndTraction/TurboExhaust) was a fiasco. The turbo seems to spin freely, and shaft sideplay seems reasonable (0.4 mm or so). It was made from all new parts (except turbine housing). But something can be wrong...

- or serious clean-air leak. We ruled this out earlier, after the pressure measured right after the turbo was only a few kPa higher than MAP; but with the 60mm tubing it might not result in too big pressure drop, even with a 100 Hp air leak. So it has to be reopened

BoostControl is very important on this engine for several reasons

- first we tuned with the factory injectors (and FPR) of the 3B engine. These injectors cannot handle the max power of the engine, but boost didn't want to climb anyway, so this was not a problem after all. Now the bigger injectors are in, so this reason is gone

- it doesn't sound like it makes much sense to tune with small injectors than upgrade and retune, but we want to be have a reasonable starting tables for a near-factory engine ("only" cooler is changed, and K26/27 turbo)

- the engine is still under break-in; well, not really any longer

- the general rule is to tune safely, go up little at a time

- a reasonably tuned boostcontrol makes the tuning runs much more reproducible. Eg. press throttle fully, and let the boostcontrol make sure the same MAP is maintained. This is nice when comparing runs with slightly different timing.

- boostcontrol makes the car more drivable, by adjusting boosttarget lower as the throttle is released a bit

Wastegate diaphragm problem

We measured airpressure at the pre-cooler nipple to find out why MAP would not climb above 206 kPa: if it's coldside or exhaust-side problem.

The kPa => Voltage of the 400 kPa (in WebShop category sensors/external MAP sensor) sensor we used:

ambient 101 kPa / 380 kPa * 4.6 V - 0.02V = 1.2V, examples:

- kPa V

- 100 1.19

- 150 1.80

- 200 2.40

- 250 3.01

- 300 3.61

- 350 4.22

- 400 4.82

When MAP peaked at 206 kPa, we measured:

- 208 kPa (=2.45V) precooler pressure when only the pressure sensor was hooked up, . => CLEAN AIR NOT LEAKING

- 154 kPa (=1.84V) precooler pressure when the pressure sensor was hooked up, while hose also connected to wastegate top (directly, no valve!). => CLEARLY INDICATES THAT WASTEGATE MEMBRANE LEAKS. The only place it could leak was the wastegate membrane: remember that we measured proper 208 kPa pressure by only removing the wastegate connection (and changing a VVV to VIV pneumatic connector, but that was not leaking).

Note that we did not detect the broken wastegate membrane when blowing by mouth ! It seemed to hold pressure.

- a tire inflation compressor would be dangerous.

- however, the best way to test wastegate is by applying some pressure at the bottom from a small tire-inflation pump

- one expects the valve to start move up at a certain pressure (you can probably hear it even if the wastegate is mounted)

- we did not hear the valve move, but the wastegate was hissing at the wastegate top hose, and even at the wastegate top screw (!!!)

Wastegate diaphragm replaced => but boost still won't go close to target

- I want to complete the

- boost procedures

- MT ini files

- and code soon, with some luck this long weekend

- EVERYONE: summarize your suggestions BoostControllerAdvanced

- or other page you find appropriate

- in short, reasonable size PWM-reference table'''

- not 1 referencevalue (20/40/60/80 %)

- not 12x12 (or 16x14) either

- comparison of the original PID to the "simple-boost"

- MembersPage/TeppoKalske 's Notes: openloop is fine as it is (since 1.1.30 the overboost PWM cutoff is not applied in openloop)

- closed loop tps-scaling is the problem (I have to think about what that means.)

- probably that simple-boost PWM does not depend on scaling (it neglects boost-target altogether. Configuration is absolute, not relative to boost-target. I think it should be relative).

Wastegate connection

The factory wastegate is used. It is suitable for much bigger airflow than the limit of the current K26/27 (appr 400 Hp).

However, the wastegate has 2 springs .. what a hack ?

We'll see if the springs are sufficient (not strong enough with the broken membrane).

- is the audi membrane possible to change ?

- kalske: easily Even though some parts may be a bit stuck after 20 years. Membrane part number 035145797B

DROPPED: this connection was under investigation, used by some dragracers with big-turbo:

- MAP => bottom of the wastegate

- this means the wastegate is closed quickly when TPS is released (eg. gearshift)

- top chamber of wastegate, via 3-way solenoid

- to athmosphere when boost solenoid is unpowered

- to boost pressure when boost solenoid is powered

This would allow controlling boost in a reasonable range:

- from little boost (wastegate opening above ~130 kPa)

- up to extreme boost, when the exhaust pressure opens the wastegate despite the rather strong springs

- note that with solenoid duty=100%, both sides of the pneumatic actuator get virtually the same pressure (MAP=boost, at least when TPS=100%)

- however, at TPS=90% and below ("part throttle), MAP < boost, which would try to close the wastegate and raise boost => this negative change requires intervention from the boostcontrol electronics (decrease duty). Theoretically possible to tune right, but bad tune could destroy the turbo fast.

While the above would be optimal in a dragrace car that only sees WOT and no throttle, part-throttle might be problematic.

DROPPED traditional setup:

- boost => WG_bottom

- boost via restriction => WG_top

- athmospere via solenoid => WG_top

In this traditional setup boost pressure opens the wastegate, relatively easy to setup the controller to do the right thing. When it works, it might make sense to investigate the more aggressive pneumatic connection. But it will never allow 280 kPa with our spring.

Se we need to be able to command boost to WG_top while decreased boost (or athmo) to WG_bottom:

- WG_top valve1: athmo (unpowered) or boost (powered)

- WG_bottom valve2: boost (unpowered) or athmo (powered)

2 solenoids are needed, each are 3-way and operated parallel (electrically). This allows very fast control, and very wide range of operation, including full boost to WG_top only.

Boostcontrol solenoid - pneumatic valve

The factory 3-way solenoid is available (greasy, but likely works). We also have boostcontrol solenoid from [webshop Pneumatic valve 3way]

Either should work.

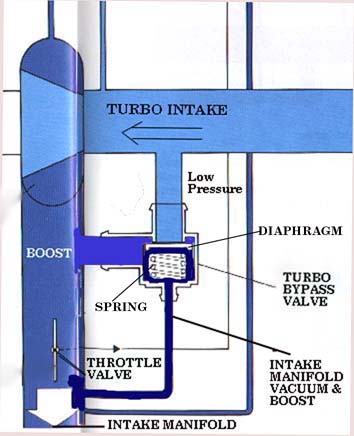

BOV - Blow-Off Valve

A factory [BOV] (also called as "Bosch bypass valve" is installed to protect the tubes, cooler and compressor from pressure spikes when the throttle is suddenly released. Some claims that this valve cannot handle 1.8 bar boost. It's very hard for me to believe this - at least if the MAP hose is connected to the top of the BOV. Anyway, we'll see.

- inlet connected to boost between charge cooler and throttle (good)

- out-tube vents to athmosphere. Since we have no MAF (to worry about "wasting metered air") this is allowed

- but it would be nicer to connect it pre-compressor. Will be possible after the airbox is made.

- With the cone-filter... it's not feasible. But at least a small filter on the output would be nice to prevent dirty-air backflow at idle

WHAT IS THE PROPER DIRECTION FOR THIS VALVE ? Which is inlet and out-tube ?

See

http://www.vems.hu/gallery/main.php?g2_itemId=344

for how mine was connected. The boost-air came in via the bigtube opposite the reference-nipple.

Also note that the BOV opens at idle, feeding unfiltered air (aka JUNK) to the engine.

Can someone check these ?

Most notably

and

These are consistent (also with the bentley manual).

My bypass valve was installed reverse, but I changed it so boost now enters at the side of the BOV. Even with this, max MAP is 206 kPa, Mmax=340 Nm, and max power is slightly under 300 Hp. Not enough (target is 270-280 kPa and 440 Nm).

from irc...

- emil_: people connect them backwards sometimes

- mk1_G: I've connected it with boost entering at the bottom (opposite the reference nipple): same way as on factory SAABs

- gedu: VAG and Saab use different bosch partno parts, might be slight design change o allow different mounting? Saab "Viggen" by-pass is priced same with VAG "710N" version, at least here in Finland. I know for sure, that Saab version can take 2.7bar absolute pressure mounted "the wrong way", where VAG one might say goodbye before that.

More points of airleak?

The car can hiss at many places. Even outside the engine bay. Even at the right-rear wheel !

- what is the soft airtube that comes under the audi200 backseat, near the battery ?

- something related to central locking ? Is central locking system pneumatically operated (not electric) ?

- there is a rather big (10mm or so) air hose from the manifold, that goes to a yellow something (apparently a check-valve, or splitter?) with 2 outputs. The 2 outputs continue in 2 thin hoses, on enters the firewall at the left (drivers side), the other at the middle.

Why does the audi200 need vacuum at so many places ? Even though mine has hydraulic braking.