After some consideration of my options, I'm almost set on going with VEMS for engine management. Anything that's cheaper is far less intelligent, anything that's more intelligent is also more expensive.

The car is an '89 S13 200SX w/ a built CA18DET engine. 1809ccm, 4 cyl, turbocharged, intercooled, multipoint sequential FI, COP ignition.

WORK IN PROGRESS

Subpages:

Starting attempt

Unsuccessful, won't start. Symptoms:

- + engine cranks, RPM shows up, ~180

- + MAP shows 90kPa

- - doesn't smell like fuel at all at the exhaust, I don't think fuel is injected. Cranking pulse is 1.9ms (1809 ccm disp., 1000cc injectors.)

- - can't make triggerlog, after the first logged white(sectrigger?) pulse, RS232 communication is lost (returns in a few seconds after closing triggerlog window OR when cranking is stopped <- TBC which). When triggerlog window is not open during cranking, comms stay up.

- / Nissan count shows 16. As in, 16 is the value shown in the Nissan count gauge. Not 104, which would mean 16 sectrig pulses, according to the manual. Is this bad, or was there an update in the software to show actual length but not yet updated in the manual? Because 16 is the correct length of the longest window, see CAS chapter below (16,12,8,4).

- / TRIED both Pri.trigger settings of Rising edge/60 BTDC, and Falling edge/28 BTDC, no difference

- / TRIED also Nissan_SR20_16_4_8_12 trigger settings, which looked quite strange, no difference

Will attach screenshot of triggerlog in the evening, but as described, one white pulse, and it's over, comms break.

- At 115200 and 57600, triggerlog freezes communications.

- Sometimes there are 2, 3 sectriggers recorded, sometimes even a primary, well, it's a game of luck, depending on the position the engine stopped last time, I suppose.

- The triggerlog is functional at 19200, but secondary pulse count was incorrect. In the one issue I've tried, 167 sec pulses were counted between two primaries. There must be 90.

Suggestions received from VEMS support:

- move RS232 ground to EC18-pin17

- * no change, but RS232 comms definitely problematic

- * when COM port in Win Dev Mgr is configured at above 19200, VemsTune data reception is laggy, intermittent. E.g. I keep moving the throttle pedal, and every 3 seconds, there's a 1 second pause in the gauge. A power cycle of the ECU fixes this, as it falls back to 19200.

- So, high-speed serial doesn't work, that's one thing, but the engine not firing at all feels unrelated to this.

Ideas:

- increase injector latency at 8 and/or 10V? Got the latency values off the Internet, seemed credible, though.

Q/A With Vems Support

Lets start with the basics, to diagnose why you might be having problems getting the engine started, could you provide:

- triggerlog of engine cranking 8-10 seconds no ignition or injection fuse; a common cause for triggerlog failing is either

- cranking too short (keep a minimum of 8-10 seconds)

- ecu reset when starting to crank caused by power dips, easily solved by connecting a strong battery near the engine not in the booth or using some small battery.

- triggerlog of engine cranking 8-10 seconds no ignition or injection fuse in safe mode, to trigger safe mode, change VT->Ecu calibration, prohibit low byte from its current value to some other value and burn, remember to put back the original value when done

- vemslog of a similar cranking sequence (cranking 8-10 seconds, no fuses)

Please upload these files with appropriate names to FileArea (or other storage space) and link here

I'll review and make some suggestions on how to proceed (and what to adjust). Thanks!

Best regards, Dave

Re: Q/A With Vems Support

Hi Dave, my problems at the moment are twofold:

- 1. high-speed serial comms do not work (see above, 19200 works, more is problematic)

- 2. engine won't fire

Do I need to fix #1 before I can address #2? I have the Nissan stock CAS, that's 180 sectrig pulses per crank rotation. This is the highest frequency of all CAS's out there that I know of. Do I need higher RS232 speeds than 19200bps to make an accurate triggerlog and/or vemslog?

I don't think my ECU resets during cranking, I get continous quick updates of the Vbatt value in VemsTune during cranking @~8V, I'm guessing serial comms would disconnect, and the gauge would freeze, if the ECU would reset due to low voltage.

I can make logs tomorrow afternoon, if 19200bps is enough.

Kind Regards,

Balazs

Hello Balazs,

A1. Serial comms over 19200 is not needed at cranking, if your serial communication is working stable at 19200 no need to worry.

A2. We are not aiming to actually start the engine just yet, first we need to diagnose if everything on trigger side is working properly

A3. ~8v during cranking is definitely way too low, attach a big fully charged battery to front with proper jumper cables (no booster) as suggested by me earlier.

To get to the bottom of this:

- apply trigger configlet: "Nissan_4cyl_SR20_360_16-4-8-12_Camsync" do not make any setting changes to this, even if it looks strange and press burn

- power cycle the ecu

- make sure you have 4 window sensor connected to primary trigger

- make sure you have the 360 window sensor connected to secondary trigger

- supply the triggerlogs and vemslogs i for earlier (using that exact procedure) and upload the actual triggerlog and vemslog files (not png screenshots or other) somewhere, link them here.

I'll review and make some suggestions on how to proceed (and what to adjust). Thanks!

Best regards, Dave

Hi Dave,

I've uploaded a .triggerlog and .vemslog with the Nissan_SR20_16-4-8-12 trigger defaults (powercycled the ECU after burning). They are of the same cranking run.

http://www.vems.hu/files/BlownHemi_11454/

I didn't do the prohibit_h thing, I just pulled off injection and and ignition in the engine bay (it's quite quick and simple in my case, just 2 connectors next to each other). I've charged my battery, last time it was seriously depleted from all the cranking I did before. It's now cranking ~9.5V, as you'll see from the vemslog.

After I made the logs, I've also cranked a long one with injection and ingition in place. I took a few deep whiffs afterwards from the tailpipe, and it's as if I can detect a faint smell of gasoline.

What's a realistic cranking VE value? Is the cranking pulsewidth in the ballpark for this configuration, conditions (~25*C)? 1.8 liters, 4cyl, 1000cc low imp. injectors?

Also, for some reason, from time to time, I find that injector settings change from Simplified to Traditional. Simplified was my setting, but I've checked after the logged cranking, and again it has gone back to Trad.. I've set it back again to Simp. During the logs it was still Trad. Does the Nissan_SR20 default or something else implicitly change this setting?

The triggerlog look quite different from when I've tried with my own settings. Without the Nissan_SR20 defaults, I had lots of white columns with some blue columns, now it's just blue+green pairs, no whites. I'm guessing this setting changes internal trigger behavior substantially. I've looked at quite a few pages in the wiki and almost all of the manual during the research phase, and didn't find any details about these trigger options. It's just a basic "if you have this, select that" guide. I'm not expecting a deep system level documentation about the workings of the trigger circuit/software, but a bit deeper explanation might aid in self-diagnosis for those of us who are not just pure petrolheads, but engineers as well.

Thank you in advance for any help,

Kind Regards,

Balazs

Hello Balazs,

I have reviewed your files:

- triggerlog looked good, no issues there

- vemslog did seems to have missed the cranking section, all it contained was some throttle blips, no rpm; perhaps you included the wrong one ?

- triggerlog with prohibit enabled is still needed to rule out any secondary trigger/sync issues, please upload this together with the vemslog containing small cranking rpm.

No need to worry about any fuel related now, first im trying to diagnose (remotely) if the basic requirements are in place, this is needed before all else.

Thanks! Best regards, Dave

Hi Dave,

I've added two new .vemslogs, dated 18:20-ish, made in Safe Mode. I don't know if recording a triggerlog and recording a vemslog are mutually exclusive, if they are, probably that's why the previous one doesn't contain anything, both are from the same cranking, when I've activated trigger logging.

Forgot the triggerlog in safe mode, I'll make one tomorrow.

P.S. one change I've made for these two logs is, I've doubled my req_fuel. When I've configured it initally, I halved it, just like I read in the guides, in preparation for doubling the VE resolution this way, but after halving the calculated req_fuel, I forgot completely to actually double table/cranking VE's. I've turned off safe mode, and it definitely smells like fuel now. Still won't fire though, pity, I really though that was gonna be it.

Kind Regards,

Balazs

Hello Balazs,

- vemslog and triggerlog are NOT mutually exclusive that's why i asked for both

- i requested until all verifications are complete you run these tests without IGN and INJ fuses (or you can unplug the connectors to ignition and injectors as you elaborated before).

- there is a proper order to preparing a car for first startup:

- determine correct trigger handling and setup/connections (that's what we are doing right now)

- verify if coils can be sparked in test mode (with plugs outside the engine)

- verify correct firing order in Ignition outputs visual and correct TDC after the trigger using timing light

- only after completing all of the above is it needed to reconnect the injectors and worry about fuel related settings

Best regards, Dave

Hi Dave,

I've uploaded a triggerlog made in safe mode, dated 09.26.55.

Kind Regards,

Balazs

Hello Balazs,

Safe mode is enabled, good; but your triggerlog does not contain any engine cranking, reminder of what is needed:

- triggerlog of engine cranking 8-10 seconds no ignition or injection fuse in safe mode

Thanks! Best regards, Dave

Hi Dave,

maybe I'm doing this all wrong then. Since I don't see any Start/Record or Stop/Save buttons, I assumed by opening Tools/Record_Triggerlog the recording starts, and closing this window stops and saves it to the auto-dated filename. Is that how recording works, or am I missing something?

Kind Regards,

Balazs

Hello Balazs,

Opening the triggerlog dialog starts the recording, correct; But without you cranking the engine (while the triggerlog capture is running) trigger pulses are not captured. If needed you can Stop and Start the recording with Start V3 and Stop V3 in left bottom corner.

- more triggerlog help is available in the VT program (see help) or online: http://vems.hu/vt/help/main/tools/triggerlog.html

Best regards, Dave

Hi Dave,

so, the problem with the triggerlog was the following. 8-10sec cranking wasn't enough. That's why you didn't see the cranking in the previous triggerlog. I had to crank for 13-14secs, for any data to actually show up, even data from 6-7 seconds before. When I stopped at 10 seconds on previous occasions, this didn't happen, the log stayed empty except for the safemode indicators. I've now uploaded a triggerlog that actually contains something besides the safemode indicators, I hope it proves useful.

Kind Regards,

Balazs

Hello Balazs,

I have reviewed: v3.3_u011454-2016-08-07-16.25.11.GOOD.triggerlog, looks good; we now have confirmed good trigger operation (of both primtrig and sectrig) on engine.

Its now time to advance to the next tests:

- make sure Safe Mode is disabled and reconnect the coils (coils only no injectors)

- verify if coils can be sparked in test mode (with plugs outside the engine) in Ignition outputs visual.

- verify correct firing order in Ignition outputs visual and correct TDC after the trigger using timing light

- set cranking advance (VT->Start/Idle->Priming/Cranking/Afterstart->Cranking advance) to 0 degrees and make a TDC mark at 0 degrees on crankshaft pulley

- with timing light verify ignition advance

- adjust primary trigger->tdc after the trigger if needed or if deviation is bigger than 180 degrees adjust output rotation.

- only after completing all of the above is it needed to reconnect the injectors and worry about fuel related settings

Best regards, Dave

Hi Dave,

- coils can all be sparked in test mode on the right outputs

- timing lined up perfectly with crank pulley marks (shifted ignition outputs down by one, and increased TDC after to 112 degrees)

Regards,

Balazs

Addendum:

Thank you for the help so far!

- Shifted ignition outputs another two steps down, since the above still didn't result in a running engine. Aligned injector outputs to ignition outputs.

- Engine now runs, but won't hold idle, has to be kept alive by throttle application. Idle reference curve setting has zero effect. No access anywhere to measure actual voltage on IAC solenoid, unfortunately. Can't remove the valve either to check visually, I can't access the bottom bolt at all.

I'll check continuity from harness to the idle solenoid again, lacking a better idea. But since the stock ECU had no problem starting and holding idle with this same valve, I suspect a misconfiguration, but I have no idea where. I've connected it to InjH output, configured it to InjGroup 7 channel on the dialog. It show up in the Idle config and the Outputs dialog correctly as well.

Addendum2:

I've taken out the Injector H pin (EC36-pin17) from the connector, grounded it, RPM jumped up by 500. So, IAC hardware is working correctly. There's something not right on the VEMS side.

It is configured to InjGROUP channel 7 non-inverted. I'm assuming, maybe wrong, that this is the Injector H ch.128 output, EC36-pin17?

Reference DC curve is set to 95% all the way from cold to warm. Changes here have no effect.

Hello Balazs,

Great to hear you were able to complete the steps in order and to have it resulting in a running engine!

I would recommend one change still:

- your TDC after the trigger is outside of the recommended range of 60-70 degrees for simple trigger. i know that the trigger itself can be rotated on the sr20 (and alike), please adjust the trigger counter engine rotation by ~20deg on cam so your tdc after the trigger drops to around 62-65ish.

Regarding the idle control, if you post a vemslog of engine running (which also has your current configuration) and link here i can review what might be causing the issue.

Best regards, Dave

Hi Dave,

I've uploaded my current config and a vemslog dated 2016-08-15. My TPS is at 3%, I've gapped it with a washer so that I don't have to keep my foot on the pedal. Otherwise, it is otherwise calibrated correctly at 0-100.

- I had to give back the timing light I borrowed, so I can't check timing for a while. What functional disadvantages and/or limitations are there while the TDC after is outside of the recommended range?

Thank you,

Kind Regards,

Balazs

Hello Balazs,

with the TDC after the trigger outside of the recommended range you might have some timing inaccuracies, i would strongly recommend to adjust it.

I have reviewed your vemslog (v3.3_u011454-2016.08.15-17.36.42.vemslog) and was able to pinpoint the source of your IDLE problem, you have assigned the idle valve to INJgroup/7 (which is good) but you have not assigned a pin to this group in Base setup->Injector outputs visual (this needs adjusting) in your case you should tick the last checkbox to assign INJgroup/7 to EC36-pin17.

From general running review it seems your engine is running quite uneven on cylinder 2 (see Injector calibration view), i suspect there might be some injector unbalance, HV leak, plug cable not properly connected or coil failure.

Best regards, Dave

Hi Dave,

Thanks, I'll add that tick tonight.

What do you mean by unevenness on cyl2? Sudden low/high spike in AFR or RPM, or some other in/out variable? What should I look for in VemsTune and/or the log? I'd like to diagnose this myself by swapping components around, like coils/injectors/plugs.

(I can hear aslight unevenness, a misfire-ish event every now and then at idle, heard it on the the old ECU as well.)

Also, there is an option in the Secondary trigger settings I don't understand:

- Ignore sec.trigger pulses above RPM, and it's recommended setting is 3100. Why is it recommended to ignore the sectrigger pulses above 3100? It's exactly there where accurate ignition timing starts becoming really important.

Kind Regards, Balazs

Hello Balazs,

You can check the cylinder balance in View->Group->Injector Calibration (or press ALT+5) the columns in the gauge represent relative power per cylinder (normally on a smooth running engine they should be around even).

The sectrig setting Ignore sec.trigger pulses above RPM, keep this its at recommended value, it will not impact timing accuracy. The secondary pulses are used to determine what initial window we are in (by pulsecount) but due to the high frequency of these pulses they are a lot of wasted time at high rpm, so they are ignored above 3100rpm; timing reference is always the primary trigger (4 window) not the secondary (used for check and sync).

Best regards, Dave

Hi Dave,

I'd like to ask a few more questions, if I may.

- I couldn't find a guide/help about this Inj. Calibration screen, is there one?

- What do the microsecond values in the Inj. calibration mean, technically? What time parameter is actually measured here?

- What is the cylinder numbering scheme here? You said cyl 2 is running uneven. On the inj. calib. I see two columns out of "balance", one is below average, labeled "1", the other is above average, labeled "4" on the top (3-1-2-4 is mynumbering at the top).

- I have two strange symptoms (I think I've had these before, too, but of course, couldn't diagnose them with the stock ECU) I've uploaded a vemslog and a cfg, about the current state. I have disabled EGO correction, and flattened VE and timing around the idle cells, to better observe what happens.

- Lambda fluctuates a lot (well, I think it's a lot).

- You probably can't see in the log, but I hear a misfire-like event every now and then, a sudden, short break in exhaust pulsing.

- Are any of these related to each other, or the imbalance above?

- Are any of the above normal for a small (1.8) engine running with big (1000cc) injectors?

Uploaded log and cfg:

v3.3_u011454-2016.08.17...

Thank you,

Kind Regards,

Balazs

Hello Balazs,

The individual power gauge represent difference in rpm period between ignition events on a smooth running engine (all even) there should little to no difference. The numbers above the columns represent cylinder number, but only if you set them up correctly in Ignition outputs visual. Make sure you selected the correct firing order for your engine and that your output channel going to coilX (on cylinder Y) has Y in front of it. If not use the rotate buttons next to real cylinder order to shift.

Have not reviewed your vemslog yet, as all of the current Q's seem to be related to either some hardware problem (misfire, injector flow difference, coil problem or other) or tuning.

My suggestion would be the following:

- adjust the timing so tdc after the trigger is in the recommended range

- find the cause of the uneven running (this will related to some hardware on the engine, not VEMS hw or settings)

- tune the engine :)

Best regards, Dave

Hi Dave,

I have

- swapped the coilpack with a neighbouring cylinder -> no change

- swapped the plugs with a neighbouring cylinder -> no change

- measured resistance from harness pin to engine bay connector (~1,5m wiring + injector) -> 2.3-2.4 ohms

- measured the series current limiting resistors -> 6.3 ohms each

- for the hell of it, I've set 120% injector trim to the deviant cylinder -> it went to even, or in the ballpark, at least

- Do I have an out-of-spec injector, or could I be masking a dozen other faults with this experiment?

- apparently the injectors deviate. Maybe 6.3 Ohm series resistor limits current too much and that can make things worse. Perhaps 4.7 Ohm series resistors are better for this injector. (with active flyback it is possible to change inj PWM percentage in software (usually 38..44%).

- Does VEMS have any features that can help me make sure?

- it is virtually impossible to tell from software that a cyl misfires because of ign or injector HW problem (injector induction would be possible to measure, but if your DVM measures same resistance as the other injectors, that is good enough indication of electric health => not mechanical health of course)

- Do I have an out-of-spec injector, or could I be masking a dozen other faults with this experiment?

(On my previous build, Cyl 3 (the deviating one) showed signs of running hotter, that runner of my tubular manifold rusted much quicker at the head flange on Cyl 3 than the others.)

Thank You for any other suggestions you may have, I understand this issue is now out of the VEMS domain.

Kind Regards, Balazs

Hi,

Update: swapped injectors to a brand new set (these are high Z 12ohms, deleted the resistors). The old set had an unreliable injector. Idle is now noticeably nicer. Cylinder imbalance still there.

Question: can the imbalance be caused by that cylinder down on compression?

Thanks, Regards, Balazs

Hello Balazs,

Did you also adjust the tdc after the trigger and recalibrate the timing with timing light like i suggested ?

Regarding the indivdual power difference still present. This can be caused by anything that might be causing a power difference, like:

- uneven injector flow

- uneven air flow:

- check/adjust your valve clearance

- check for leaking valves (usual cause broken valve spring or slightly bent valve)

- piston ring leaking or stuck causing compression diff (easy to check most of the above with simple compression/leakdown test).

- bad spark energy or leaky HV cables.

I hope these hints provide you with enough information to narrow it down.

Best regards, Dave

Hi All,

I've decided two switch from LSU4.2 to LSU4.9. Can you clear up a few things for me?

- Which +5V is preferred as the source of the Nernst pullup, MAP +5V, or TPS +5V (pullup installed outside) ?

- 27k is so weak (and almost constant 20uA current) that it matters little. EC36/28 or other constant +5V preferred.

- With a pullup already installed, is it still possible to switch+configure back to an LSU 4.2, if needed?

- it is very common to use LSU4.2 with 27k nernstpullup. Haven't seen official statement from Bosch, but Haven't experienced problem with that.

Thank you, Regards, Balazs

Hello Balazs,

Please follow the wiring instructions on (take care [LSU 4.9] has different connector [pinout]): http://vems.hu/vt/help/v3/v3_wideband_settings.html

- As +5v source, when mounting the pullup externally, use MAP +5v

- Ecu's which come with internal pullup from the factory are also compatible with LSU 4.2, the pullup (external or internal) does not hurt LSU 4.2 operation.

Best regards, Dave

Hot Flyback = node30 (not node 15)

- I (Balazs) have the (EC36/23) Flyback pin (injector common 12V supply) always at 12V hot (node30)

- instead of 12V switched (node15)

While the ECU is powered (obviously) from a switched 12V source. Could this type of wiring have damaged something inside the ECU, especially in the injector area, like drivers, or flyback circuitry?

- all injouts, p259 and some other outputs are connected through diodes (common cathode connected to EC36/23 or transient diode=EC36/23+max 30V), cannot currently think of problem it can cause if battery switch or similar thing is not used.

(I carried this over from the OEM wiring, where injectors are wired directly to BAT+ .)

Either during normal operation of a running engine, or while disconnecting the battery terminal without disconnecting the ECU first? Or maybe the opposite?

- power off ECU, disconnect ECU, disconnect battery terminal is the safe order. Disconnecting battery without powering off ECU, especially with running engine, especially with a battery kill switch might cause damage ( => only use "battery kill switch" in case of emergency).

- Disconnecting the battery (even if EC36/23 = node 30 constant 12V) is unlikely to cause damage (as far as I see), if engine is not running and ECU is powered off (even if ECU is still connected to EC36 and EC18)

- welding maybe ? (might damage electronics anyway, anything special around grounds or power supply might make it even more susceptible)

Hi!

Is the

- cylinder numbering in the Inj./Ign. Output dialog windows' leftmost side

- cylinder numbering in the Injector Balance page columns?

If no, what's the translation between the two?

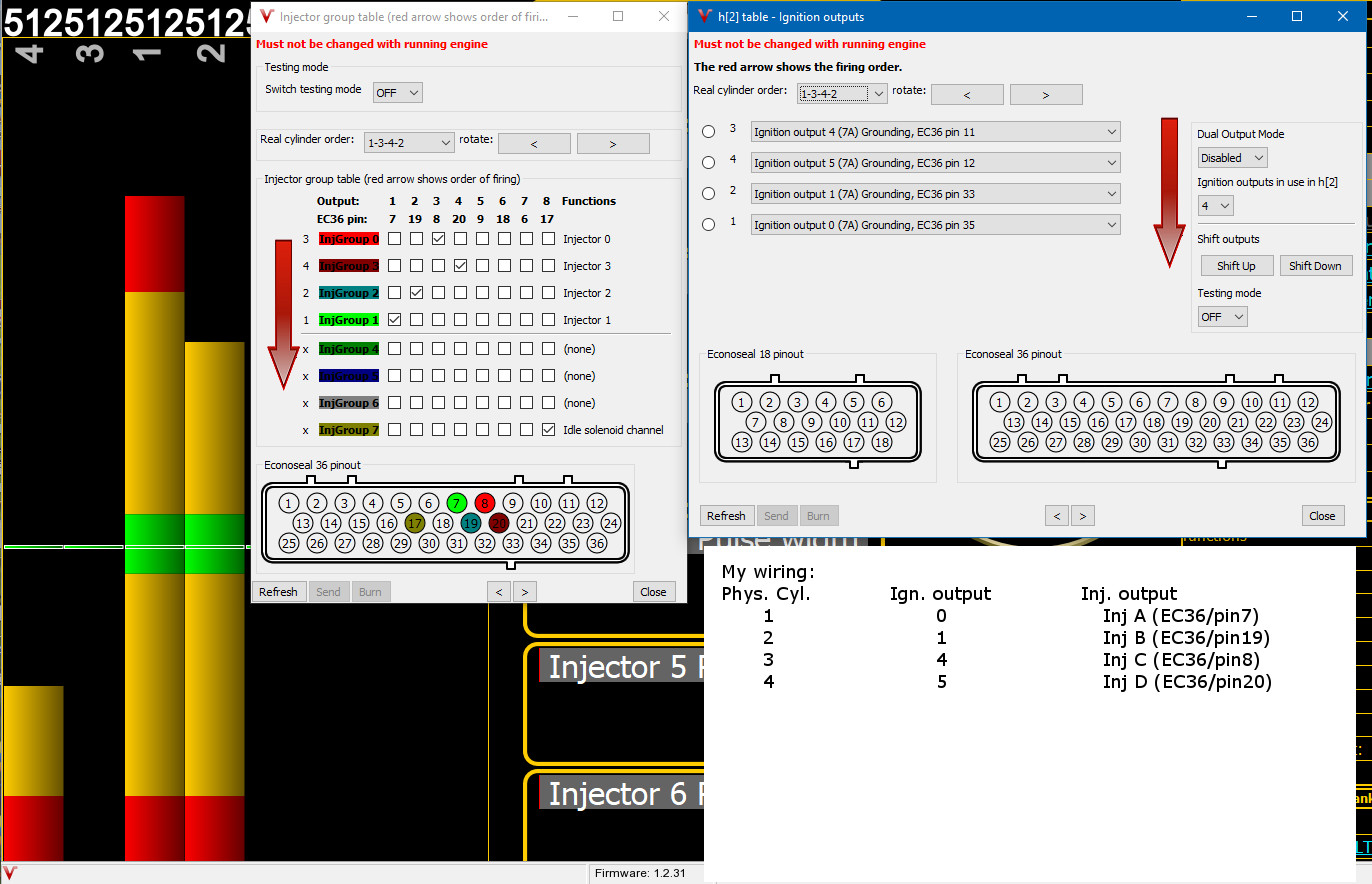

If yes, and I have lined up my configuration like below (wiring in bottom right), if I disconnect either the Physical #1 injector or ignitor, should the column labeled "1" drop? (And the same for every other Physical cylinder's and inj/ign, respectively?)

Thank You,

Kind Regards,

Balazs

Hello Balazs,

The answer to all your questions is: Yes :).

But with a small side note: that only works if you are using camsync otherwise the numbering might be 360 crank degree off, if you set up the firing order labeling correctly and have confirmed (for at least ignition outputs), that cylinder number left of the output selector actually fires the coil of that cylinder.

Best regards, Dave

Hi!

Thanks!

I was asking, because I have the following strange phenomenon with the Inj-Balance column numbering:

If I disconnect an Inj/Ign, power drops in a different numbered column, than the physical Cyl# I disconnected. Despite "Logical" cylinder (left column of numbers) numbering being aligned with the Physical numbering (as above).

I've checked assignments again in Test Mode on Inj and Ign outputs as well. The correspoing coil sparks, and the corresponding and only the corresponding Inj clicks. Logical numbering in Inj-Visual and Ign-Visual matches my Physical numbering.

| disc. Physical Cyl# | Inj | Ign |

| resulting power drop in column numbered | resulting power drop in column numbered | |

| 1 | 3 | 3 |

| 2 | 1 | 1 |

| 3 | 4 | 4 |

| 4 | 2 | 2 |

Rearranged into firing order:

| Physical Cyl# disconnected | 1 | 3 | 4 | 2 |

| Logical Cyl# power drop | 3 | 4 | 2 | 1 |

So it's actually shifted by one.

Q: Could there be a misconfiguration on my part, or is Vems-Tune not displaying correctly for this engine/trigger configuration?

Engine is running. Some cylinders are somewhat out of balance (see above), but running fairly "normal" otherwise.

It's a run-of-the-mill four cylinder, 1 injector and 1 coil per cylinder. Nissan SR20 type trigger with the 16, 12, 8, 4 windows. I have cam sync, no banked injection or wasted spark.

What makes me suspicious about Vems-Tune not displaying correctly, is that about 2 times out of 5, when I:

- open up a logfile

- open Ign-Visual dialog

- switch to Inj-Balance page

- press ">" in Ign-Visual,

- the numbering on Ign-Visual+Inj-Visual ROTATES

- the numbering on Inj-Balance page DOES NOT rotate

On the second+ press, everything rotates, but Inj-Balance does not make up that first missed rotation. (I have witnessed the same also when connecting to a live ECU, but I haven't tried it as many times as opening just logfiles, so I can't tell an OK/NOK ratio for the online part.) So there seems to be some inconsistent behaviour.

I'm using VT 1.5.57 (2018-01-04), updated ini files to the actual, and using e.g. this logfile:

http://www.vems.hu/files/BlownHemi_11454/v3.3_u011454-2019.05.18-17.21.02.vemslog

Thank You,

Kind Regards,

Balazs

Hello Balazs,

I was able to reproduce the individual power gauge not following on the first rorate press in other dialog; there seems to be some dangling state there. Luckily there is an easy fix on refresh it correctly follows. A dual ALT + 5 (after first rotate press after VT statrtup) shouldfix it.

It is possible to adjust the shift factor between rotation offset and display individual power manually by editing v3gui.cfg file in your VT install dir/config (at end of file) IndividualPowerShift=3 is default, in your case IndividualPowerShift=2 should have the desired effect.

I hope this solves your column display problem, please note this only changes the displayed number above the column not the column data itself.

Best regards, Dave