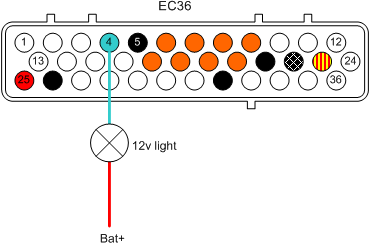

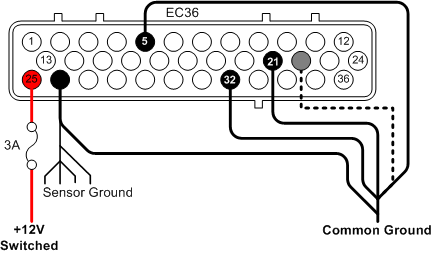

+12V Supply

- EC36-pin25 3A Fused +12v supply

Note

that if you have moved the battery to the rear of the car you may want to run

separate wires for the starter/alternator and for the cars electrical system to

the battery. Otherwise the several meters long cable will cause a significant

voltage drop during cranking that will cause the ECU to reset when the battery

starts to run low. This may prevent the car from starting even if the engine

cranks over.

Once you have

connected and checked the continuity of ground you can connect your VEMS unit to the EC36 plug and apply the power supply. There

is little point in connecting power until the serial connector or LCD screen

has been connected.

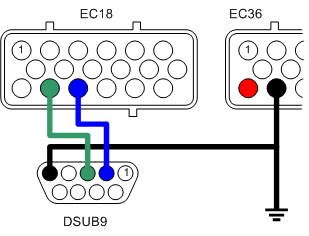

Connecting

serial port

To allow the

connection of the VEMS unit to your PC a serial port

plug must be connected as follows.

- EC18-pin14 to

DSUB9-pin3

- EC18-pin15 to

DSUB9-pin2

- EC36-pin26 to DSUB9-pin5 (GND).

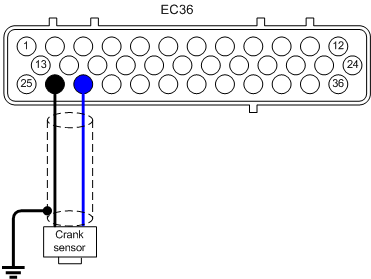

Connecting the

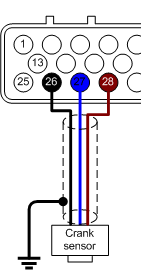

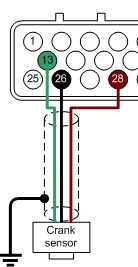

primary trigger (CAS)

Magenetic sensor / Variable reluctance (VR)

Mechanical

considerations (need to be written somewhere and referenced from here)

The VR sensing circuitry is very sensitive to electrical noise,

shielded cable (coax) must be used and good grounding is vital.

- EC36-pin27 VR+ Note that some other ECUs trigger on positive-going edge so their schematic

might mark the + and GND swapped: so don't

blindly follow naming from autodata pinout or some schematic, keep in mind that + and -

might need to be swapped.

- EC36-pin26 VR-

Hall Sensor

VEMS is available configured

for Hall sensors, these are more noise tollerant and

require a +5V supply.

- EC36-pin27 Hall

signal

- EC36-pin26 Ground

- EC36-pin28 +5V

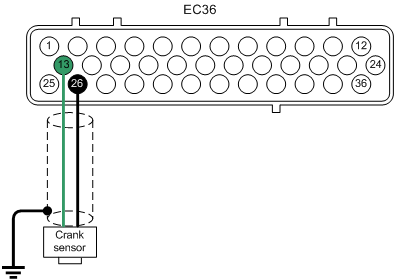

Connecting the

secondary sensor (optional)

Magenetic sensor / Variable reluctance (VR)

With the same considerations with the primary trigger regarding

electrical noise.

- EC36-pin13 VR+ (central wire in coax)

- EC36-pin26 VR- (shield and ground)

Hall Sensor

- EC36-pin13 Hall

Signal

- EC36-pin26 Ground

- EC36-pin28 +5V

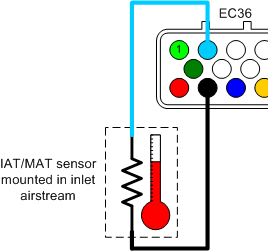

Connecting

the inlet air temp. sensor (IAT)

- EC36-pin2 Signal

- EC36-pin26 Ground

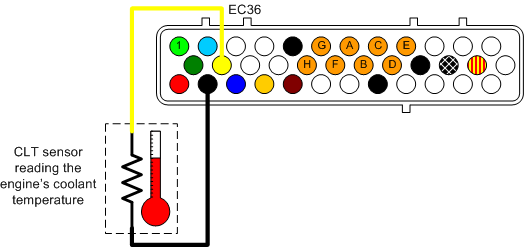

Connecting

the coolant temp. sensor (CLT)

- EC36-pin14 Signal

- EC36-pin26 Ground

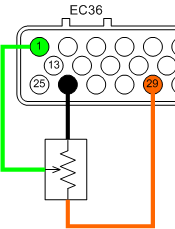

Connecting the

throttle position sensor (TPS)

The throttle

position sensor is used by VEMS to provide fuel

requirements in Alpha-N configuration and acceleration enrichment.

- EC36-pin29 TPS (+5v) out

- EC36-pin1 Wiper out (0-5v)

- EC36-pin26 Ground

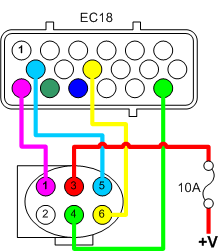

Connecting WBO2 Sensor

- EC18-pin13 to WB6-pin1 (Nerst Cell

Signal)

- EC18-pin7 to WB6-pin5 (WBO2 Pump-)

- EC18-pin18 to WB6-pin4 (WBO2 Heater)

- EC18-pin9 to WB6-pin6 (WBO2 Pump+)

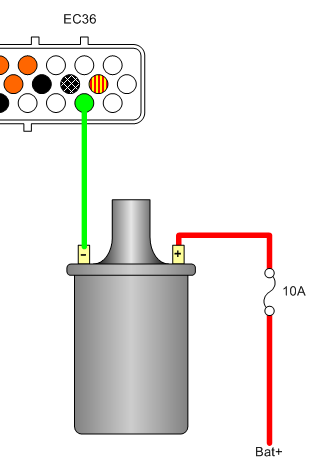

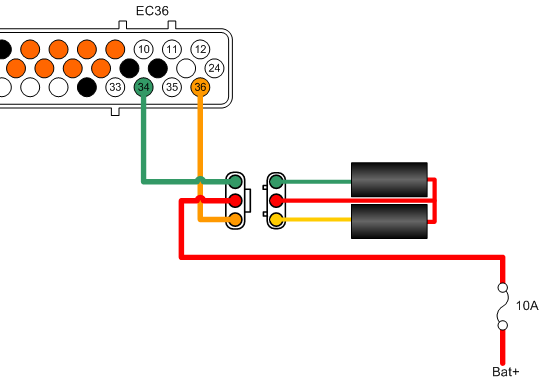

Single coil

In some

instances you will want to keep the distributor, in this case VEMS can be configured to use the original coil as shown.

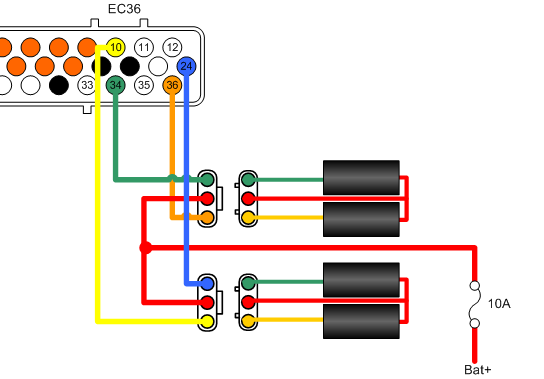

Coil pack

Connecting a

two coil (4 cylinder wasted spark)

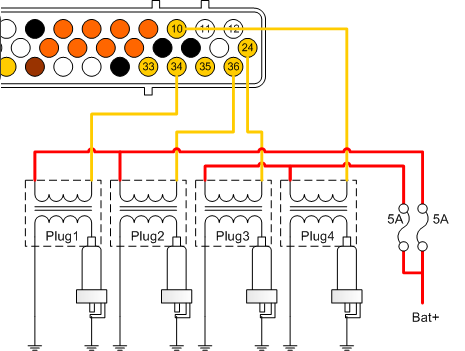

Additional

coil packs, for applications such as 8 cylinder wasted spark

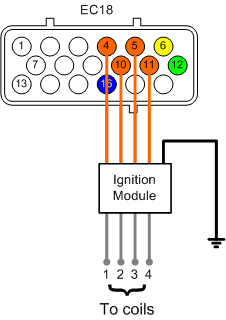

Coil on plug (COP)

Individual

Coil connections are shown, the pins connect to the negative '-' side of the

coil.

Using the

Stepper Motor Driver to control Ignition

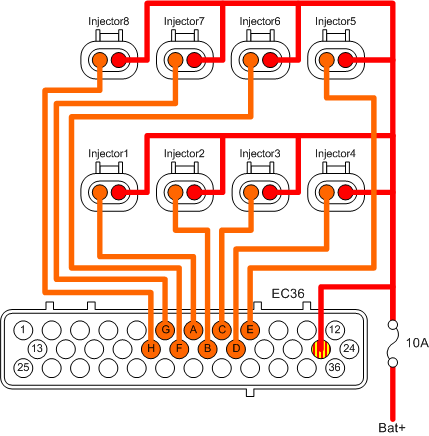

To 8 injectors

are wired as shown here.

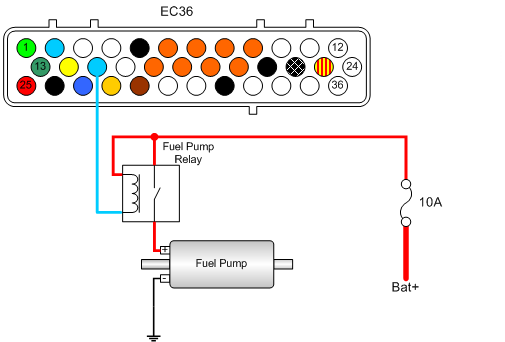

Connecting the

fuel pump

The fuel pump

is controlled via a mechanical relay.

- EC36-pin15 to relay coil

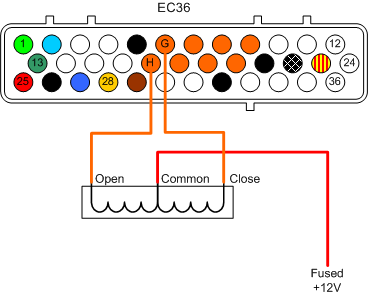

- EC36-pin6 to IAC close pin

- EC36-pin17 to IAC open pin

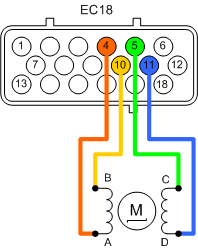

Stepper Motor IAC

The coils are preferrably connected between A-B and C-D stepper outputs:

- EC18-pin4 Stepper-A

- EC18-pin10 Stepper-B

- EC18-pin5 Stepper-C

- EC18-pin11 Stepper-D

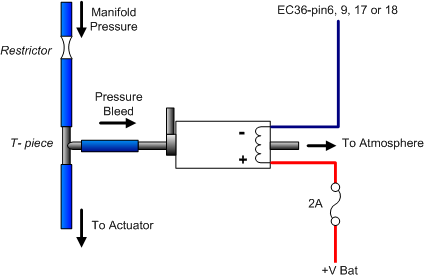

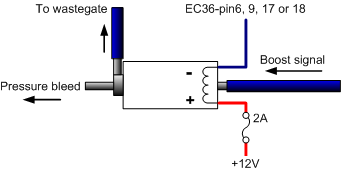

Connecting A Boost Control Solenoid

This assumes

the use of the Webshop 3-port pneumatic solenoid

Connecting the

pneumatic ports

Integral wastegate

actuators

Connection option one

Connection option two

Using Low Current Drivers for a Shift

Light

Connect a 12v

indicator lamp to a switched supply and taking your choice from the table above, connect the lamp's second pin to the VEMS.